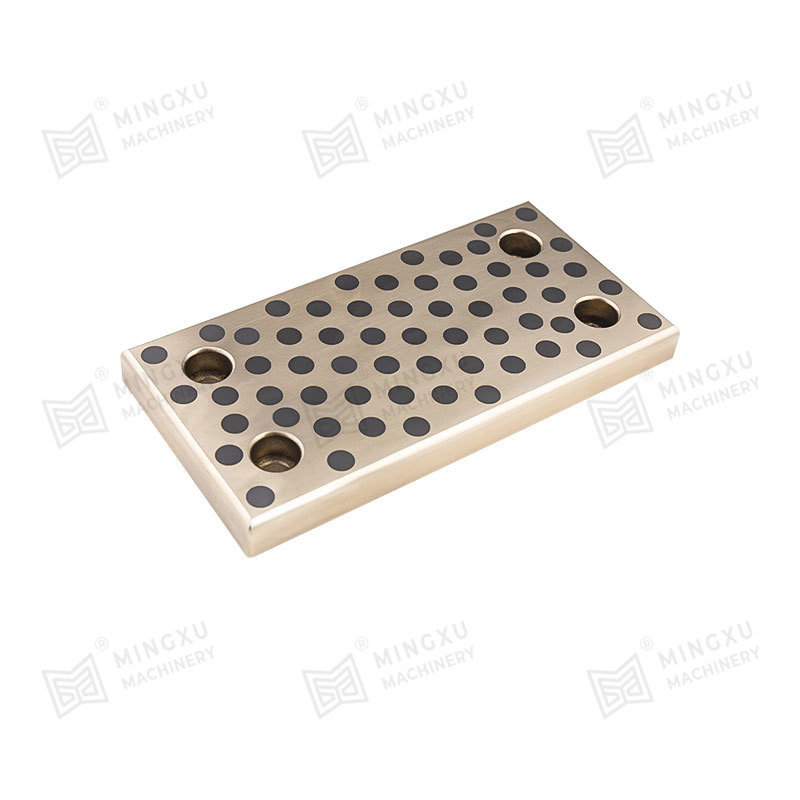

MXB-DU Oilless Ferens SF-I Bushing High-Tempus Repugnantia

Cat:Oilless supportantes

MXB-DU Oilless Ferens (etiam SF-1 bushing notum) est illapsus cum lamina ferrea involutus ut basis, sinterae sphaericae in medio pulveris aenei, et...

Vide Details Metallurgical machina operates sub extrema condiciones summus temperatus, gravibus onerat et severus pulvis contaminationem. Traditional Plabfol Lebolet gestus frequenter deficient propter oleum volatilizationis, ipsum depositionem et clogging, ducens ad INCONDITUS apparatu shutdowns. Self-Lubricating Bearings, leveraging eorum inhaerent lubrication possessiones, Excel in tutela, liberum operationem, summus temperatus resistentia, et contamination immunitatem, faciens ea discrimine upgrade ad metallurgical apparatu.

I. Typical Applications in Metallurgical Machinery

1.1 continua casting apparatus segmentis RUBILIS

Collerem temperaturis saepius pervenire 400-600 ° C, causing conventional uncto-lubricum gestus ad carbonize et deficient. A domesticis ferro molendini adoptavit Graphite-inlaid aeris, secundum auto-lubricating gestus (CUSN10 XX% Graphite). Post sex menses continua operatio in secundarium refrigerationem zonam continua tria, gerunt erat solum 0.3 mm-ter longior quam uncto-lubricatis, cum non opus est oleum replenishment.

Data ex Hispanica Steel molendini ostendit quod sub summus temperatus conditionibus, haec gestus ponere a firmum frictio coefficiens 0.12-.15, reducing superficiem scalpendi defectus in cast

1.2 calidum volubilem molendini roll gestus

Subvolvente pressuras nimis 2,000 tons, metallum, secundum auto-lubricating gestus (E.G .: Steel, backed aeris mixturae) potest sustinere superficiem pressures usque ad LXXX MPa. Thyssenenkrupp scriptor 2,250 mm calidum habena Mill causa studium demonstrandum quod firmamentum volumine ferre postea cyclis extenditur a III hebdomades ad XII weeks, salute € 1.2 decies annuatim in sustentacionem costs.

Impact-repugnans Design: A Multi-iacuit compositum structuram (ferro retro aeris pulveris iacuit PTFE PTFE CXX) tolerat apicem impulsum onerat de CXX MPa per volvens.

1.3 inspiratione fornacem Top Distributors

In summus temperatus, pulveris Gas environments (CCC ° C, CC g / M³ pulvis concentration), Ceramic-fundatur auto-lubricating gestus (E.G., SI₃n₄ BN) Excel. Baisteel scriptor MMXXII RETROFIT ostendit quod distributor afferentem vitam auctus a II mensibus ad VIII menses, cum pulvis-gerunt resistentia improvidus per LX%.

1.4 frigus volubilem molendini tensio cylindro coetibus

Sermo frigus rolling postulat humilis-vibration gestus. A Japanese company employed PI (polyimide)-based self-lubricating bearings, achieving vibration values ≤1.5 μm at 1,200 m/min line speed—50% lower than conventional solutions—ensuring strip thickness tolerance of ±0.5 μm.

II. Key lectio criteria et technica cubits

2.1 summus temperatus resistentia

| Material Type | Maximum temperatus | Apta applications |

| Graphite, aeris composita | D ° C (DC ° F Burdient) | Continua casting, reheating fornacem Rollers |

| Ceramic gestus | DCCC ° C | Inspiratione camino gas systems |

| Steel, backed ptfe compositum layer | CCLX ° C | Frigus Rolling Equipment |

2.2 contaminationem resistentia et gerunt resistentia

Metallurgical pulveris (Fe₃o₄, sio₂) habet Mohs duritiam VI, requiring materiae cum superficiem duritiam ≥hb200. Tertio-pars probat ostendere quod wc-iactaret auto-lubricating gestus redigendum gerunt rates per LXX% comparari ad vexillum gestus in environments per X% alumina pulveris.

Per ISO 4378-1, Metallurgical Gestus oportet transiet ≥100-hora quartz harenae erosion probat (fluunt rate XV m / s).

2,3 Lond capacitatem verificationem

Static onus: Segor Seger-Basterings oportet resistere Static Superficiem pressuris ≥100 MPA (GB / T (XXIII) DCCCXCIV Latin).

Dynamic onus: Rolling Mill Gestus oportet occursum dynamic onus factors ≥3.0 (Laudate DCCXXXII Latin).

2.4 scelerisque expansion compatibility

Metallurgical apparatu saepe experitur scelerisque deformatio. Control differentia in scelerisque expansion coefficientes inter GRUDING et Substratum:

Steel subiectum (cte XII × 10⁻⁶ / ° C) binos bene cum aeris-fundatur gestus (CTE XVIII × 10⁻⁶ / C) C).

Ceramic gestus (cte III × 10⁻⁶ / ° C) requirere expansion ultricies structuras.

2.5 sumptus-efficaciam analysis

Secundum ad MMXXIII Metallurgical Machinery ferre foro fama, auto-lubricating enterings cost 30-50% magis initio sed redigendum totalis sustentacionem costs per LX%:

A medium-sized Mors Mill Conscidisti continua casting linea sustentacionem costs ex ¥ 820.000 ad ¥ 350,000 annuatim.

Volvere molendini ferre postea tempus omissa a XVI horas ad IV horas per instantiam.

III. Industry trends et lectio suasiones

3,1 technological trends

Extreme-Condition Materials: Titanium DIBORIDE (Tib₂) -reinforced Aluminium Aquilonem et Pendent 1/3 de ferro sustinere 1,000.

Smert Condition Cras: Sweden scriptor SPHF offert GRAT3 et integrated Temperature / Vibrationis sensoriis pro realis-vicis ONERO et gerunt alerts.

3,2 practical lectio tips

Prioritize Products Certified to ISO (IV) CCCLXXVIII (illapsum afferentem temptationis) et ASTM E228 (scelerisque expansion coefficientem temptationis).

Crescere ferre Clearances ab 20-30% super vexillum cogitationes ad compensare pro scelerisque expansion in metallurgical applications.

Request venditor-provisum pulvis environment scamnum test tradit (potissimum cum combined summus temperatus gerunt impulsum onus testis).

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. Habet specialized in auto-lubricating ferre R & D et vestibulum per a decade, promerendae positivum feedback ex metallurgical machinery clients. Nam inquisitiones contactus: [email protected] .

MXB-DU Oilless Ferens (etiam SF-1 bushing notum) est illapsus cum lamina ferrea involutus ut basis, sinterae sphaericae in medio pulveris aenei, et...

Vide Details

MXB-FB090 Aerea Coiled Ferens est frugi portans capacitatem cum magno onere et indumento bono resistendi a CuSn8 aeneo involutus. Operatio superfic...

Vide Details

MXB-JTLP laminam se-luctantem obsistentem praebere potest vexillum producta ab latitudine ab 18mm usque ad 68mm et longitudinem ab 100mm usque ad 2...

Vide Details

MXB-JGLDW cancellos ductoris sui lubricantes fiunt per instrumenta machinae CNC robore aeneae altae. Superficies solidis unctionibus intexta est ut...

Vide Details

Construitur a summo gradu Graphite-aeris ally, McB-JSL L-genus auto-lubricating dux Rail est opportuna installed in FORM Clamping Guide in fingunt ...

Vide Details

Vexillum MGB9834 DIN9834 dux bushing vexillum DIN9843 obtemperat et apto Europaeo autocineto stampae moritur. ordinatur ad regimen certae et certae...

Vide Details

MSEW JIS 20mm Latin gere, lamina summa vi aenea, stannum aereum, chalybeum bimetale, ferrum missum vel ferrum ferens. Superficies graphite (SL1) ve...

Vide Details

MJGB oleum liberorum iniectio duce frutices normae sunt compositae in processu coronae iniectionis adhibitae, quae ducatum gratuitum praebent et su...

Vide Details

SF-1T formula specialis producti designati ad valorem excelsum PV condiciones operandi oleum calces sentinae. Productum peculiares habet utilitates...

Vide Details

Terminus lubricae Plumbi-liberi gestus emendantur in fundamento SF-2. Effectus eius idem est cum SF-2, sed superficies plumbum non continet, et app...

Vide Details

Nobis loquere