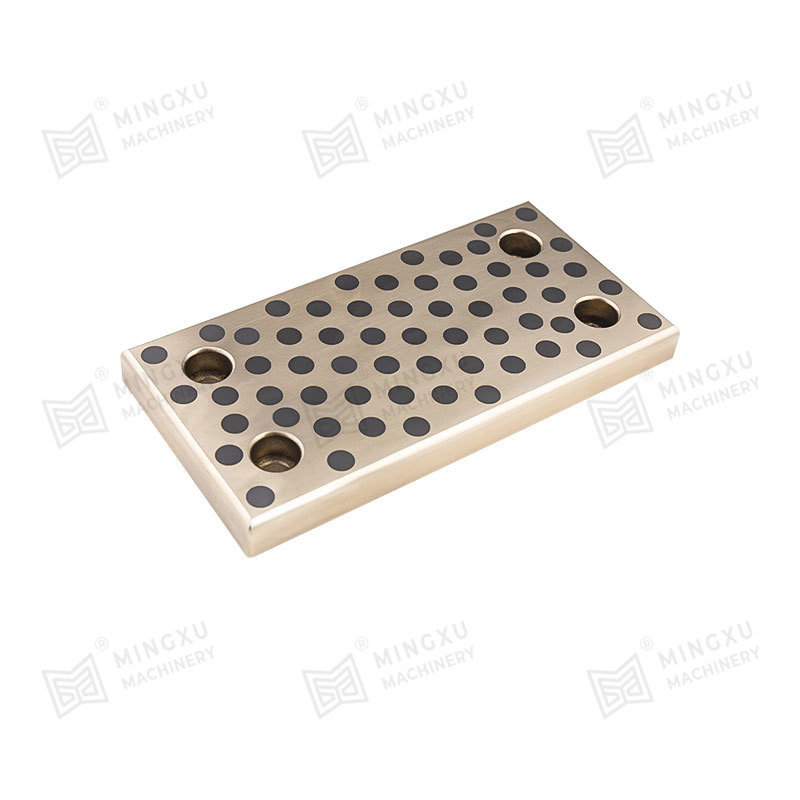

MXB-JFFB Self-Lucbricans Half Ferens

Cat:Sui Lubricating Ferens

MXB-JFFB dimidias gestus auto-lubricantes referuntur ad gestus qui solum dimidium circumferentiae stipitis vel axem tegunt, sustentare et reducere ...

Vide DetailsSolid-lubricating bearings are engineered to operate without the need for continuous external lubrication, making them ideal for demanding automotive and aerospace environments. By embedding solid lubricants directly into the bearing material, these components reduce maintenance requirements, resist wear, and perform reliably under extreme temperatures, heavy loads, and harsh environmental conditions. Their unique properties make them essential in applications where traditional bearings may fail or require frequent servicing.

In the automotive industry, solid-lubricating bearings provide numerous performance and maintenance benefits. Their ability to operate without added grease or oil reduces the risk of contamination and simplifies assembly and service intervals. These bearings also contribute to quieter operation, improved fuel efficiency, and longer component lifespan.

Solid-lubricating bearings are widely used in engine and transmission systems where high temperatures, heavy loads, and limited lubrication access are common. Components such as rocker arms, timing belt tensioners, and cam followers benefit from the self-lubricating properties, ensuring smooth operation and minimizing wear over time.

In suspension and steering systems, solid-lubricating bearings are used in control arms, bushings, and stabilizer links. Their self-lubricating design reduces friction, enhances response, and maintains performance under varying temperatures and road conditions. This also eliminates the need for periodic greasing, reducing maintenance costs.

Aerospace applications demand bearings that can perform under extreme loads, temperature fluctuations, and high-altitude conditions. Solid-lubricating bearings meet these requirements by offering high wear resistance, low friction, and the ability to function without conventional lubrication, which is crucial for flight safety and reliability.

Solid-lubricating bearings are used in aircraft landing gear, actuators, and control mechanisms. They ensure reliable operation during critical phases of flight, withstand heavy dynamic loads, and maintain consistent performance in extreme temperatures. Their self-lubricating properties also prevent contamination and reduce maintenance downtime between flights.

Aircraft control surfaces, including ailerons, flaps, and rudders, rely on solid-lubricating bearings for smooth articulation. These bearings handle high-frequency motion, resist corrosion, and operate in both sub-zero and elevated temperatures, ensuring precise maneuverability and reliability throughout the aircraft's lifespan.

Different bearing materials and designs are used depending on load, speed, temperature, and environmental conditions. The following table summarizes common types and their typical applications:

| Bearing Type | Material | Key Features | Typical Applications |

| Polymer Bearings | PTFE or composite polymers | Self-lubricating, low friction, corrosion-resistant | Bushings, control arms, suspension joints |

| Metal-Polymer Bearings | Steel or bronze with embedded solid lubricant | High load capacity, durable, temperature-resistant | Landing gear, actuators, engine components |

| Graphite-Embedded Bearings | Bronze or steel with graphite lubricant | High temperature, dry operation, wear-resistant | Wing hinges, control linkages, high-temperature zones |

Proper selection, installation, and maintenance of solid-lubricating bearings are critical to maximize their benefits in automotive and aerospace applications. Consider the following practices:

Solid-lubricating bearings are essential in modern automotive and aerospace engineering, providing reliable performance in extreme conditions while reducing maintenance needs. Their self-lubricating properties, durability, and ability to operate under heavy loads and temperature fluctuations make them ideal for engines, suspension systems, landing gear, and control surfaces. Incorporating these bearings enhances equipment lifespan, operational efficiency, and safety, making them a crucial component in advanced engineering projects.

MXB-JFFB dimidias gestus auto-lubricantes referuntur ad gestus qui solum dimidium circumferentiae stipitis vel axem tegunt, sustentare et reducere ...

Vide Details

MXB-JDB gestus sui-luctantes, etiam notae graphitae in quibus virgulta aenea inaurata sunt, novae lubricationes gestus habentium et notas metalloru...

Vide Details

MXB-DU Oilless Ferens (etiam SF-1 bushing notum) est illapsus cum lamina ferrea involutus ut basis, sinterae sphaericae in medio pulveris aenei, et...

Vide Details

MXB-DUF oleum liberum compositum ferens, etiam SF-1F bushing notum, quod volvens illapsum cum lamina ferrea ut basis, sinterae sphaericae pulveris ...

Vide Details

MXB-FB090 Aerea Coiled Ferens est frugi portans capacitatem cum magno onere et indumento bono resistendi a CuSn8 aeneo involutus. Operatio superfic...

Vide Details

MXB-JOML laminis lapsum auto-lubricantes ordinantur ad frictionem extenuandam et servitium vitae in applicationibus industrialibus extendendis. Pro...

Vide Details

MGB61 NAAMS Standard Guide Bushing certa solutio ad applicationes directas et lenis est. Hic dux bushing dispositus est ad signa NAAMS occurrere, a...

Vide Details

Duces circulares saepe in tabulis autocinetis adhibiti sunt et in magnis formis terunt. Forma basis et exonerare laminam duces plerumque uti ductor...

Vide Details

MPW VDI3357 Latin gere Plate facta est in inductione propriae solidi ducatus in loco convenienti. Metallum basis materialis onus sustinet et effect...

Vide Details

MJGB oleum liberorum iniectio duce frutices normae sunt compositae in processu coronae iniectionis adhibitae, quae ducatum gratuitum praebent et su...

Vide Details

Nobis loquere