In Cleanroom environments - de Semiconductor fabs ad Biopharma Labs - Microscopic oleum Degradation iam diu fuit Achilles 'calcaneum traditional gestus. Ut industries dis ad ISO classis I Clekroom signa, a tacere revolution est citatus: Firmus-lubined gestus sunt repositoque oleum-fundatur ratio ad eliminate contagione ad suum fontem.

Et occultatum sumptus liquidum lubricants

Traditional uncto / oleum-lublica lebicle Release volatile Organic Compositis (Vocs) per:

Thermal naufragii: friction generat calor (> CL ° F), causing lubricant oxidatio

Mechanica Shear: Gyratorium Fragium Fragmentum oleum moleculis in sub-100nm particulas

Outgassing: Hydrocarbon evaporatio Ultra-High Vacuum environments

Studies ab ASME Journal of TRIBOLOGIUM ostendere quod LXXVIII% of tangoroom particulam comitibus supra 0.3μm originate ex afferentem Lubricant Degradation - A Critica Proventus pro Wafer Lithography et MRNA Vaccine productio.

Lubrication solidae: Molecular obice

Advanced solidum-film gestus uti Ptfe-Graphite Nanocomposites et Mos₂-DLC coatings (Diamonds, sicut ipsum) ad creare auto-renovatio tritofilms. Dissimilis olea, haec materiae:

Nulla Voc Emissions: Operate sine Hydrocarbon vincula prone ad naufragii

Particula captis: Lamellar structurae captionem gerunt obstantia interius

Passivum signantes: Forma <5μm tutela layers ut repellere externa contaminantium

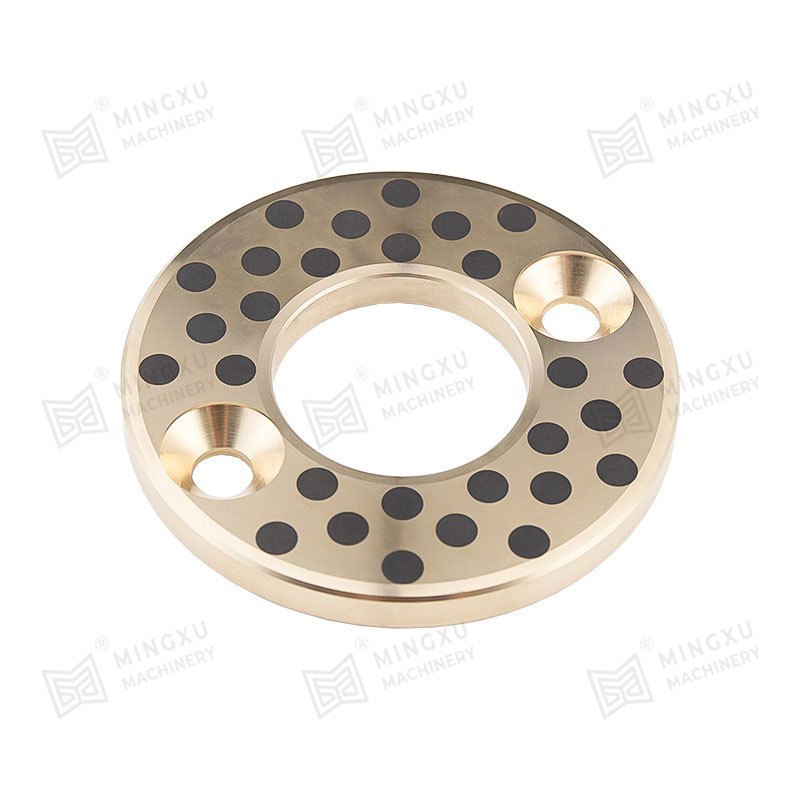

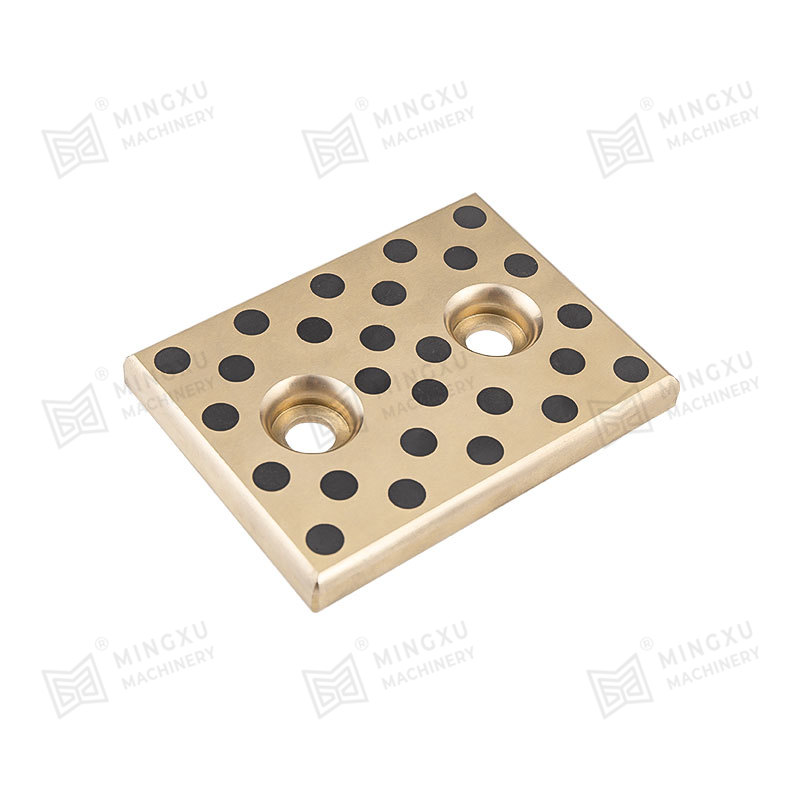

! [Ferentem crucem-section showing solid Lubricant layers]

Figura: multi-iacuit solid Lubricant architecture in Cleanroom-Promptus Gustas (Source: NASA Technical Report in vacuo, compatible Gestus)

Verus, Orbis Terrarum Impact

Case Study: Siconductor etching Tools

A Tier I Chipmaker replaced oleum-lubricated linearibus ducibus cum Ptfe-solidum gestus in EUV lithography systems:

Particularum computat reducitur a XCIII% (testimonii ISO classis I Specs)

Sustentationem intervalla ex CD ad 10,000 operating horas

Cedat damna a Wafer defectus cecidit $ 2.8M / Year per productionem lineam

Implementation guidelines

Cum eligendo solidum-lubined gestus ad bluarrooms:

Temperature fines: Most Polymer, secundum films deficere supra CCLX ° C (Opt ad Ceramic-metallum Matrices)

Load ratings: solidum Lubricants typically tractamus 20-30% inferioribus dynamic onerat vs. olea

Umor Imperium: Quidam Mos₂ coatings requirere Ducens Manufacturers sicut Igus et S.-Gobain nunc offeres gestus pre-probata ad Iest-std, cc1246d ad Outgassing obsequio.

In futurum de mundus vestibulum

Cum regulators Teligens Tullchroom particulata signa sub MMXXV semi S23 revision, solidum-lubricatae transitioning a angulus ad necessitatem. Emergentes innovations sicut Graphene-Ionic liquida hybrids promittere pontem perficientur gap inter solidae films et hydrodynamic lubricatae - sine contaminatione risks.

Nobis loquere