I. Oscillatio Oscillatione Frame Gestus: De ultima solutio contra MDC ° C Thurmalis Radialis

Et fingunt oscillatione fabrica in continua casting machinarum habet longa adversus provocationem de aeris laminam scelerisque deformationis compressing in gestus, ducens ad waveform DISCIPIUM in oscillationis et Billet Crusta Cracking, unde in ferro leakage. Innovative solutio utitur a cual10fe3 nickel aluminium aere matrix cum a XXX% gradiente graphite inlay, ubi graphite density est altior super superficiem iacuit quam in interiore iacuit, formans in superficiei gradiente quam in interiore, formatam in superficiem, quam in interiore, formatam in superficiem, quam in interioribus, formatam in superficiem gradiente. Structurally, favum microporous oleum-repono structuram (cum pore profundum 0,1mm et pore diameter 0.3mm) est disposito automatically dimittere a lubricating film super calefactio. Hoc complementum per 1.2mm-wide scelerisque expansion ultricies socors quod pressius absorbet 0.15MM / C ° C ° F. Deformatio aeris laminam. Comparari ad traditional gestus et temperatus resistentia modum habet auctus a CCL ° C CML ° C, in oscillatione deviationis est optimized ex ± 0.8mm ad 0.1mm, et in tempore per mensis ad 0,1 temporibus per annum. Post applicationem in ansteel MMCL continua casting apparatus, annua ferro lacus damna reducta RMB XXVIII decies, et portantes Service vitae pervenit XXXVI mensibus.

II. Segmentum Guide Rollerus Aeris Bushings: Nigrum Technology enim absorbuit aqua vapor et ferro cadmiae scale

Sub conditionibus DC ° C Billet Radialis, LXXX ° C High-pressionem aquae caligo, et abrasione ex HV800 duritia ferrum cadmiae, traditional aeris bushings experiri menstruam gere 1.5mm. Solutio adoptat A CUSN12 phosphor aere matrix roborari cum Zro₂ Ceramic fibris ad induendum resistentia, combined cum XXV% Graphite mos₂ inlay iacuit pro auto-lubricatae. Spiralis INCILE GROOVES (cum profundum 0.3mm et picem de 5mm) amplio INCILE Efficens a LXXX%, et superficiem laser microform abrasive particularum ne arari laser. Post exsequendam, menstruam mediocris gerunt minuitur ad 0.06mm, et replacement frequency erat extenditur a semel per mensem ad semel omne III annos, et in Billet Rate erat acriter reducitur de XVIII% 0,5%. In Baisteel Silicon ferro productio linea salvus RMB 5.1 million in annua sustentacionem costs et reducitur downgraded billet products per 2.3%.

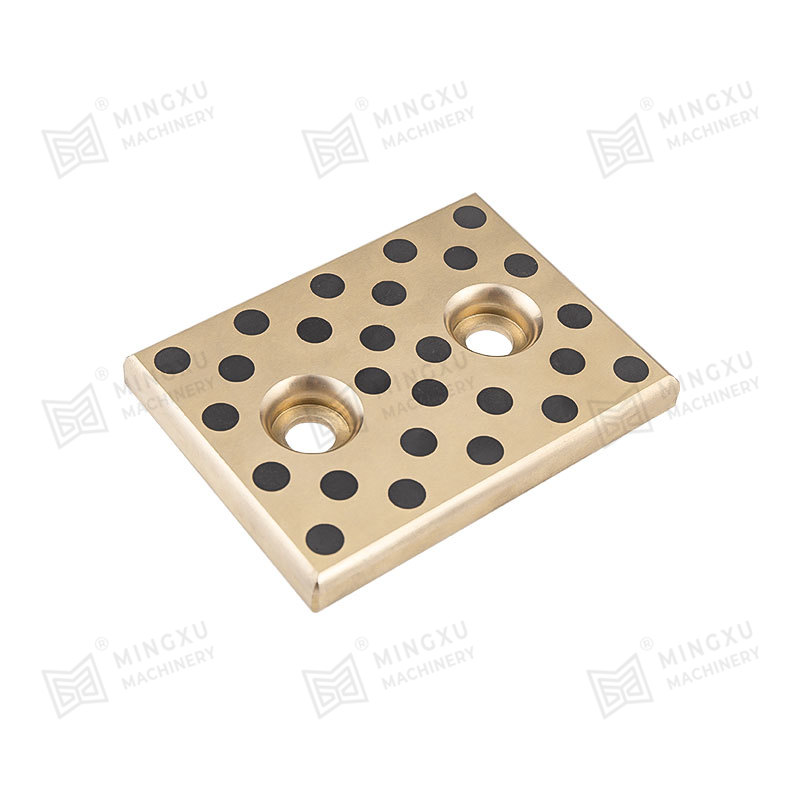

III. Cutting Car Puer Natus Plates "Energy-Borry Armor 'enim gravibus-onus impacts

To address the track crushing problem caused by peak vibrations of 200MPa and thermal deformation during flame cutting, a three-layer composite copper plate was developed: a 20mm Q345 steel plate base layer for impact resistance, a CuZn40Al sintered copper alloy intermediate layer for heat conduction and vibration absorption, and a working surface with graphite capsule array self-lubricating units. Validated per 10⁷ Cycles de 200mpae Pulsus testing secundum Iso (IV) CCCLXXXI signa, in anno gerunt minuatur ex 12mm ad 0.4mm, in rota Service vitae extenditur a VIII hebdomades ad C hebdomades, et in semita vitae ad ≤0.2mm / 10m. Shagang scriptor application demonstrandum quod cutting currus positus accuracy manebat stabilis ad ± 0.3mm in III annis, et parce pars costs minuatur a LXXXVII%.

IV. Secundarium Refrigerandam Zonam Prendia volumine portantes Housings: "aquae repellent custodes" in aqua caligo

In summus humiditas amet in secundarium refrigerationem zona ducit ad mediocris de 2.1 rubigo-adductus invasiones per mensem in traditum ferre housings. Innovation utitur a Cuni10fe Matrix cum Nano-Hydrophobic coating (Contact Angle> CL °), paribus cum centrifuga aqua-effusione structuram (automatic ad celeritates> 30RPM). Ipsam probat ostendit nulla rubigo-adductus invasiones, a reductionem in volumine superficiem pitting profundum ab 0.8mm / mensis ad 0.02mm / mensis, et vita sustentationem, liberum sigillum replacement. Et operating rate of Shougang scriptor continua casting apparatus auctus a LXXXII% ad XCVI%, unde in annua incremento in cruda ferro productio de 370,000 tons.

V. Irreplaceable genes aeris Alloys

Rex scelerisque conductivity : Cum scelerisque conductivity ≥90 w / m K (V temporibus, quod de ferro), quod rapidly dissipat frictional calor.

Abrasive particula carceris : Mollis matrix encapsulates super XCV% de abrasive particulas, ne secundarium lapsum.

Corrosio repugnans obice : In stagni / nickel passivation film praebet X temporibus in Cl⁻ corrosio resistentia ferro.

Anti-adhaesio clypeus : Graphite solvo a ipsum film super calefactio, ne summus temperatus metallum adhaesionem.

Nobis loquere