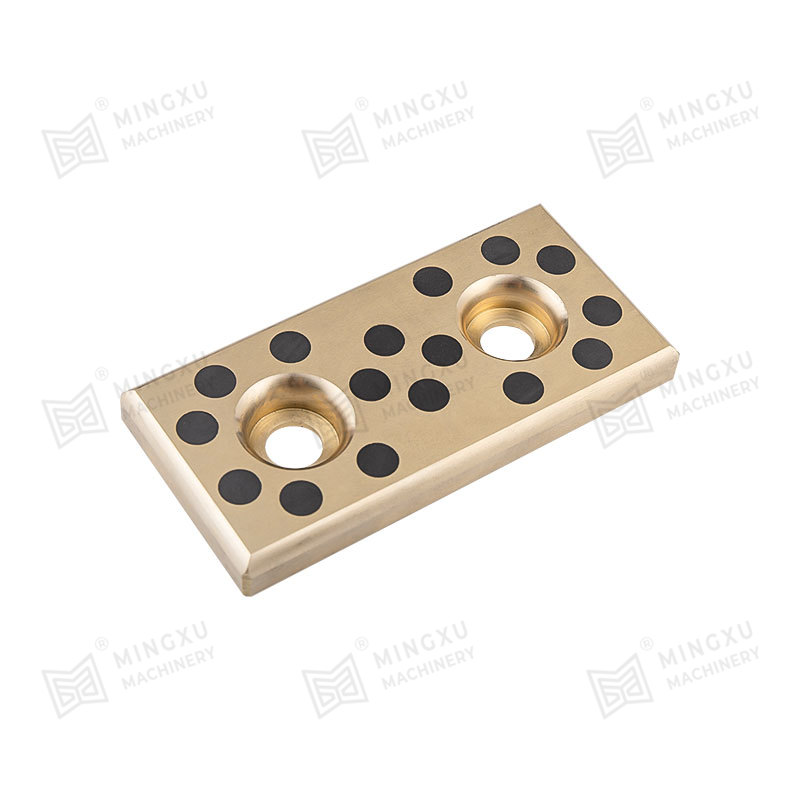

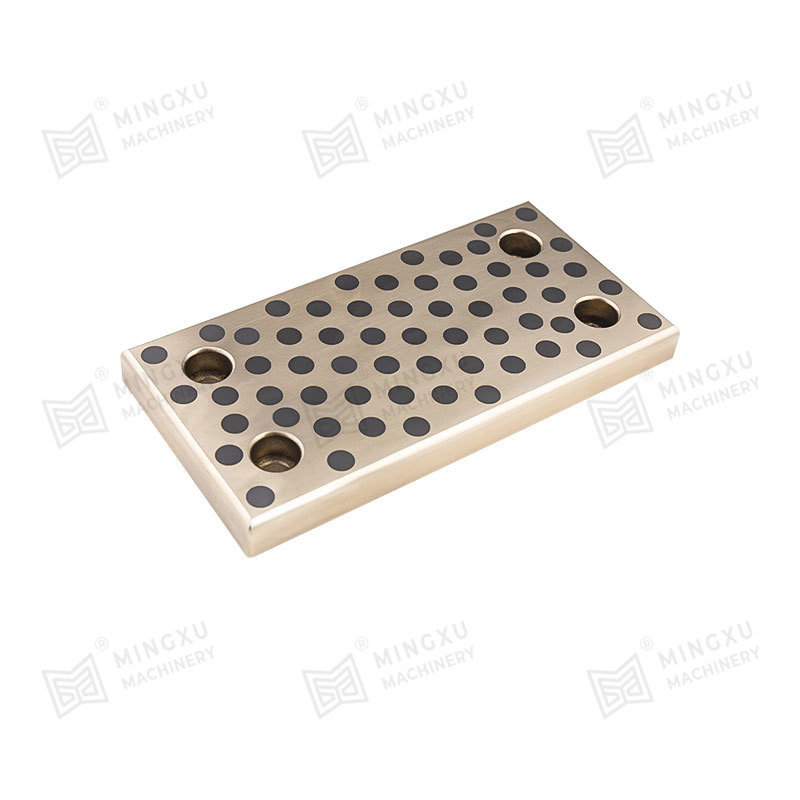

MXB-JDBU Self-Lubricans mittentem aeneum Ferens

Cat:Sui Lubricating Ferens

MXB-JDBU Sui-Lucbricans, Conjectio aenea ferens est summus effectus solidi lubricandi producti in graphite vel mos2 solidi ducatus graphite inactus...

Vide DetailsGraphite-aes compositum materiae emersit ut discrimine solutiones ad gravibus-officium gestus operating sub extremo mechanica et scelerisque passiones. Hoc studium systematice investigat tribtological Optimization of Graphite-aere laminates per microstuctrical ipsum et evaluates eorum perficientur in industriae-scale afferentem systems. Per integrationem provectus proprium ars, computational modeling et agri sanatio, ut demonstrare a XLII% reductionem in lapsum rate et XXVIII% lenimentus in onus-afferentem facultatem comparari ad conventional aeris alloys. Synergistic effectus Graphite scriptor auto-lubricating proprietatibus et aes sistens descriptiones integritas sunt quantitatis resolvitur, providente blueprint pro altera-generation afferentem materiae in metalla, industria, et gravibus machinatione in metalla.

1.Heavy-Officio Gustas Facie Relentless challenges ab abrasive gerunt, tenaces defectum, et scelerisque degradation, praecipue in applications ut ventus Turbine Gearboxes, crusher molendinos et hydraulicorum excavators. Traditional materiae saepe deficere ad statera mechanica vires cum sustinetur lubricatae sub pressuris (> II GPA). Graphite-aes laminam , Leveraging graphite est lamellar solidum lubricatae et aes ductilis, praesentem paradigm subcinctus. Hoc opus addresses duo core hiatus:

Interface Design: Quam Graphite dispersion Topology (Flakes vs. nodules) gubernat tertium-corpus tritofilm formation.

Operational fines: quantifying discrimine PV (pressura-velocitas) limine pro composita Degradation in oscillatory loading.

II. Materials et modi

2.1 compositum fabrication

Base Matrix: Cusn10 Bronze (LXXXIII vol%), pre-mixtum cum 0,5% ni ad frumenti elegantia.

Graphite Reinforcement: XVII Vol% Saccharum Graphite (5-20 μm fickes), varius per magneticam agri, assistat peccare.

Processus: Pulveris metallicy combined cum calidum-torcular peccare (DCCCL ° C, CL MPa, ar atmosphaera) ad consequi 98,6% theorica densitate.

2.2 Tribological Testing

Equipment: Pin-on-Disc Tribometer (ASTM G99), 3D Profilometry et in-situ ultrarubrum thermography.

Conditions:

Load: 50-400 N (Hertzian Contact pressura: 1.2-3.5 GPA)

Luting Velocitas: 0.1-1.5 M / S

Lubricatae, terminus regimen (olei-fame)

2.3 microctructural analysis

Fib-sem pro subsurface deformatio tabularum.

Raman Spectroscopy ad propria tritofilm graphitization gradus.

III. Results et disputationem

3,1 friction et gerunt morum

Optimal graphite dispersionem: Flake alignment parallel ad illapsum directionem reducitur frictio coefficiens (μ) a 0,38 ad 0,21 (Fig. 3a).

Gerunt mechanism transitus: Delaination-domineris lapsum infra II GPA vs. oxidative gerunt supra 2.8 GPA (Fig. 3b).

Circumspectum: Compositum Limited Temperature Surge CXXVI ° C III GPA, versus CCXVIII ° C in monolithic aes.

3.2 Tribofilm dynamics

Self-sanitatem layer: XPS confirmata Tribofilm compositionem ut Nanocrystalline Graphite (ID / IG = 0.18) Cuo Nanoparticles, repleverunt omnis 1,200 cycles.

Accentus Redistribution: Finitum elementum Modeling Revelata Graphite flava absorbet LXVII% of tondebis iactabantur, moratio crack nucleation.

IV. Industrial Application Case: Mining Crusher Gustas

Baseline: Traditional Babbitt, Metal Gustings required replacement omnis 1.200 horas.

Graphite-aere Retrofit:

Field Data: 2,050 Horae Service Vita sub 2.4 GPA Dynamic Loading.

Defectum Analysis: De-of-Vita Specimen ostendit uniformis Graphite deperditionem (

V. Hoc studium constituerit multifunctional consilio compage pro graphite-aes compositis, achieving:

Tribological Synergy: Graphite scriptor lubricity et aes lenta per imperium anisotropy.

Predictive exempla: A mutatio Archard aequatio incorporating temperatus-dependens Graphite exfoliation rates (R² = 0.93).

Industrial scalability: Validation in ISO 4378-1 obsequium ferre probat confirmat promptu, quia OEM adoption.

Future Opus erit explorare Hybrid Compositis cum MXLene additives ad Praeterea augendae PV fines in sub-nulla arcticus Operations.

MXB-JDBU Sui-Lucbricans, Conjectio aenea ferens est summus effectus solidi lubricandi producti in graphite vel mos2 solidi ducatus graphite inactus...

Vide Details

MXB-DX ambitus olei liberorum gestuum, aequivalens gestus campestris SF-2 auto-lubricatis vel siccis, quae in lamina ferrea nititur, pulveris sphae...

Vide Details

MXB-JTGLW dux cancellos auto-lubricantes resistentiam praebent et frictionem minuunt, ut vetustatem extensam et effectus augeant. Productum hoc 13 ...

Vide Details

MXB-JGLX cancellos sui-lubricantes multiplices proprietates operiunt ut princeps indumentorum resistentia, caliditas resistentia, corrosio resisten...

Vide Details

MXB-JSOL ductor sui-lubricans rail est dux sulcus L-formatus ductoris claustri sui lubrici, quod compositum est ex aere et graphite altum robur et ...

Vide Details

MGB61 NAAMS Standard Guide Bushing certa solutio ad applicationes directas et lenis est. Hic dux bushing dispositus est ad signa NAAMS occurrere, a...

Vide Details

Duces circulares saepe in tabulis autocinetis adhibiti sunt et in magnis formis terunt. Forma basis et exonerare laminam duces plerumque uti ductor...

Vide Details

MSEW JIS 20mm Latin gere, lamina summa vi aenea, stannum aereum, chalybeum bimetale, ferrum missum vel ferrum ferens. Superficies graphite (SL1) ve...

Vide Details

MX2000-2 graphite graphite nickel mixturae dispersae portatio est novum productum inter solida lubricationis gestus. Cum TF-I, hoc productum habet ...

Vide Details

SF-2S oleum liberorum lubricationis germen productum est melior SF-2, cum ferro matricis dorsi, pollinis aenei sphaerici sintered in medio, et supe...

Vide Details

Nobis loquere