The excellent performance of the combination of high-strength brass and graphite in terms of wear resistance, high-temperature resistance, corrosion resistance, high load-bearing capacity, and long service life is primarily attributed to the synergistic effects between the two materials and the complementary nature of their properties. Infra est analysis ex suo perficientur commoda ex prospectus de materia proprietatibus, structural consilio et commercio machinationes:

I. Gerunt resistentia et auto-lubricatae

Solidum lubrication effectus Graphite

-

- Graphite habet structuram quae concedit ut structuram, quod concedit ad formare translationem film durante frictio, reducing ad frictionem coefficientem (ut infra 0.05). Hoc auto-lubricating proprietas minimizes recta metallum, ad-metallum contactus, ita reducing lapsum.

- High-fortitudinem aes (ut HBSC4 / cac304) et vulvam vires, dum graphite est embedded in superficiem vel poros. Post currit-in periodum, in graphite est uniformiter dimisit usque ad continue replete in lubricating film.

Onus-afferentem et gerunt resistentia summus viribus aes

-

- High-fortitudinem aes, quibus elementa sicut cadmiae, aluminium et ferrum exhibet princeps duritia (HB≥200) et compressive fortitudinem (≥410 MPa), enabling sustinere gravibus onera et resistere.

- In scelerisque conductivity aeris Alloys AIDS in æstus dissipatio, ne localized overheating et subsequent materia mollit aut defectum.

II. High-temperatus resistentia

Inherent Temperature Resistance of Materials

- High-fortitudinem aes potest sustinere altum temperaturis (brevis-term nuditate usque ad CD ° C vel supra), ut idoneam ad altus-temperatus environments ut metallurgy et boilers.

- Graphite maintains firmum lublicating proprietates altum temperaturis et exhibet superior oxidatio resistentia comparari oleum-fundatur lubricants.

Structural stabilitatem

- Cum combined, in lucrorum effectum graphite reduces friction-generatae calor, cum excelsum scelerisque conductivity aeris mixturis celeriter dissipat calor, prohibendo materiam deformatio vel defectum.

III. ROSIO resistentia

ROSIO resistentia summus viribus aes

- Elementa sicut cadmiae et aluminium in aeris alloys formare a densa cadmiae film, enhancing resistentia ad corrosit media ut aqua et acida.

- Graphite, ut inert materia, non participare in electroChemical corrosio, et inlaid structuram reducit in contactu area inter aeris et mordendo media.

Aliquam adaptability

- Combined materiae potest resistere aquam exesa et acidum immersionem (E.G., in cibum machinatione et eget apparatu) sine postulantes additional anti-corrosio treatments.

IV. Maximum onus-afferentem facultatem et impulsum resistentia

Vires aeris ally matrice

- High-fortitudinem aes habet compressive fortitudinem (≥410 MPa) et cedere vires ut enable ut resistere altum onerat, faciens idoneam ad humilis celeritatem, gravibus, onus, aut impulsum, prone, gravibus-onus, aut impulsum-prone, gravibus, constructione, et minea et mari et apparatu).

- V% in V% in proportio Graphite est typically imperium in V% ad vitare nimia debilitavit de vulvam viribus cum optimizing onus distribution per pore vel sulcus consilia.

Anti-captum facultatem

- In graphite lubricating film prohibet tenaces gerunt inter metalla, avoiding "occupatione" phaenomena, praecipue in applications ubi oleum films sunt difficile ad formam (e.g., Reciprocating vel oscillaning components).

V. Long Service Vita et Low Sustentacionem costs

Auto-lubricatae extendit ministerium vitae

- In continua lubricatae provisum est a Graphite reduces ad lapsum rate, unde in ministerium vitae quod potest esse plus quam bis, qui de traditional aeris bushings sub oleum-liberum conditionibus.

- Et opus crebris sustentationem vel lubricant postea eliminated, reducendo downtime et sustentacionem costs.

Environmental adaptability et stabilitatem

- Et combined materia maintains firmum perficientur in dura environments ut vacuums, summus pulvis conditionibus et humiditas (E.G., in Semiconductor apparatu et Marine Machinery).

- Similis scelerisque expansion coefficientes graphite et aeris mixture reducere periculum internum accentus vel delaination propter temperatus mutationes.

VI. Optimization vestibulum processus

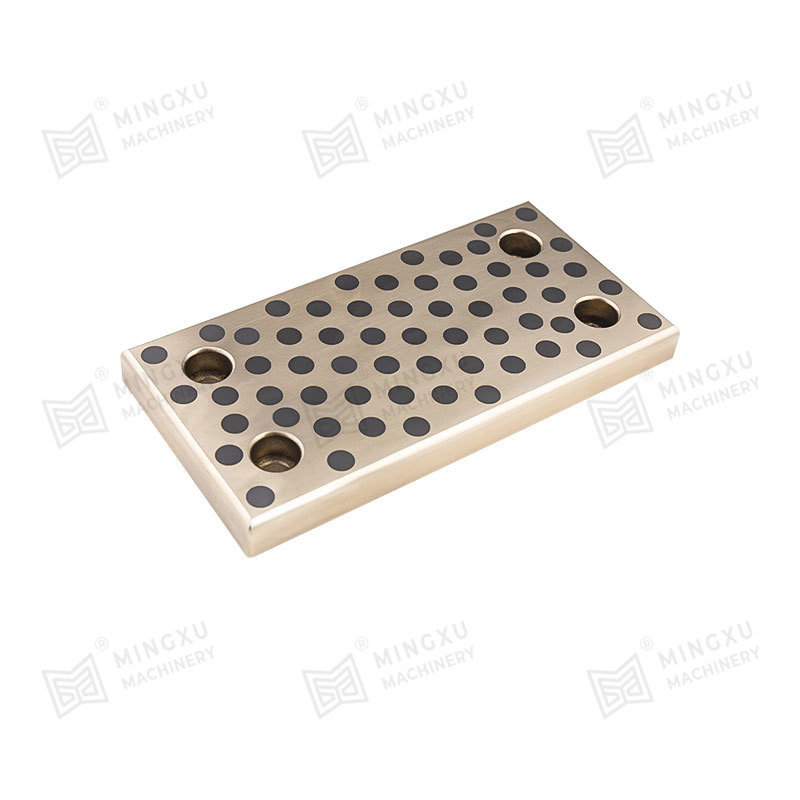

Inlaid structuram consilium

- Graphite est embedded in aeris alleo matrix per mechanica fixation (E.G., striatus, poris) vel tenaces vinculum processibus ad curare firmum release et prohibeatur.

- Manufacturers sicut Zhejiang Mingxu Machery vestibulum Co .: Ltd. capere customized productio modi, adjusting in graphite proportio, distribution, et matrix materiae (E.G., immaculatam, ferre, ferreus) ad sectam alium operating conditionibus.

Material matching et superficiem curatio

- Aeris mixturae matrix potest subire plating (E.G., stagni plating, Chrome plating) aut calor curatio (E.G., extinguitur) ad augendae et corrosio resistentia.

- High-puritatem graphite materiae (avoiding REDIVIVUS materiae) sit electus, et comminuet vires (E.G., ≥500 N pro φ8 Graphite) sit probata ut reliability.

In summary, compositum ex summus viribus aes et graphite achieves perficientur melioramentis trans multiple facies per synergy roboris et lubricatae, complementary materiam proprietatibus et optimize structural consilia. Et Core commoda includit:

- Graphite providente humilis friction auto-lubricatae, reducing sustentationem requisita;

- Aeris slow ensuring onus-afferentem facultatem et gerunt resistentia, accommodatam dura ambitus;

- Flexibile vestibulum processus enabling Aliquam ad occursum diversis operating conditionibus.

Zhejiang Mingxu Machinery Manufacturing Co .: Ltd. iam versantur in R & D et productio aeris alleo alloy components et auto-lubricating gestus in super a decade, cum dives productio et technica peritia. Nam quis productum vel technica inquisitiones, placere sentire liberum contactus nobis : [email protected] .

Nobis loquere