I. technica background et collaborative innovation valorem

Sicut Core elit de auto-lubricating gestus et aeris-fundatur materiae, Zhejiang Mingxu habet extendit patented fixture technology in aere workpieces ad dispensando de graphite aeris et praecisione, Dolor Points:

l Graphite Aeris Bushing Superficiem Donec: Traditional Clamping modi causa Graphite Layer damnum (damnum rate> XV%) et friction coefficiens fluctuations> XXX%.

l Tenues aeris plate dispensando deformatio: aeris laminas cum crassitudine ≤ I mm exhibent a machining flatness error> 0,1 mm (GB / T MCLXXXIV).

l Complex structuram positioning: Satis foraminis Position accuracy (± 0.1 mm) in processus multi-foraminis aeris bushings / aeris laminis afficit conventus perficientur.

II. Core Technology Analysis et Collaborative Product Applications

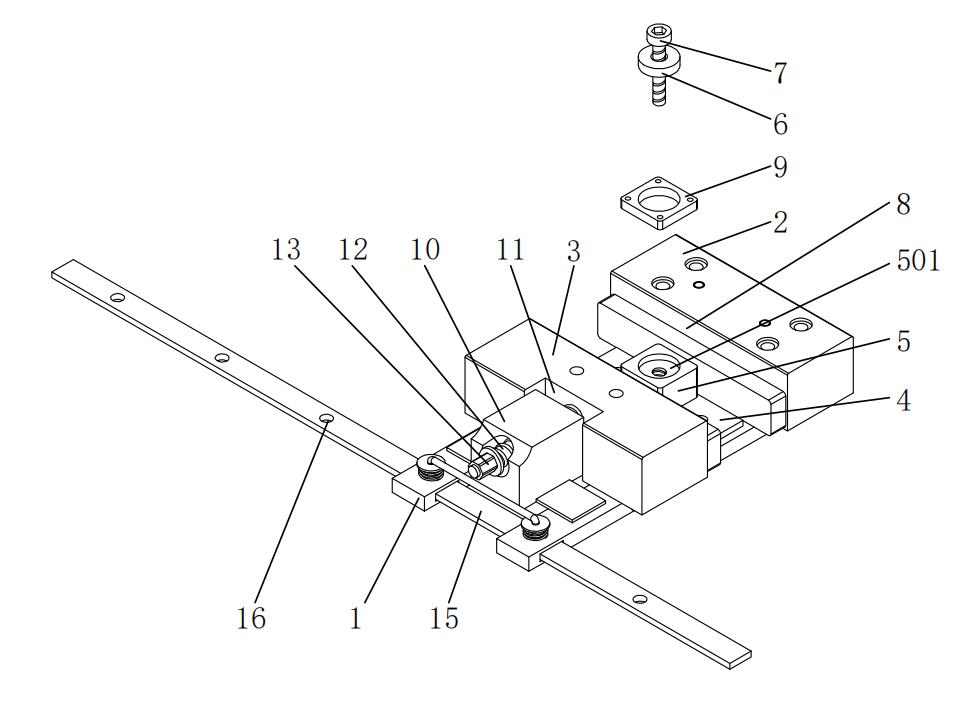

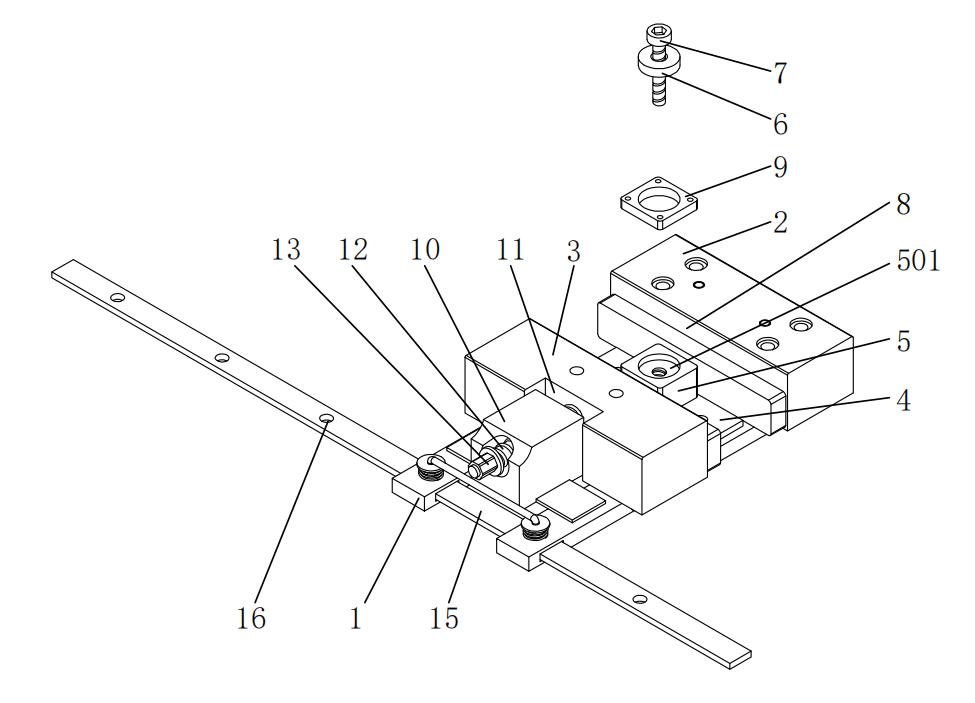

I. Multi directional vis clausa-loop cogere ratio

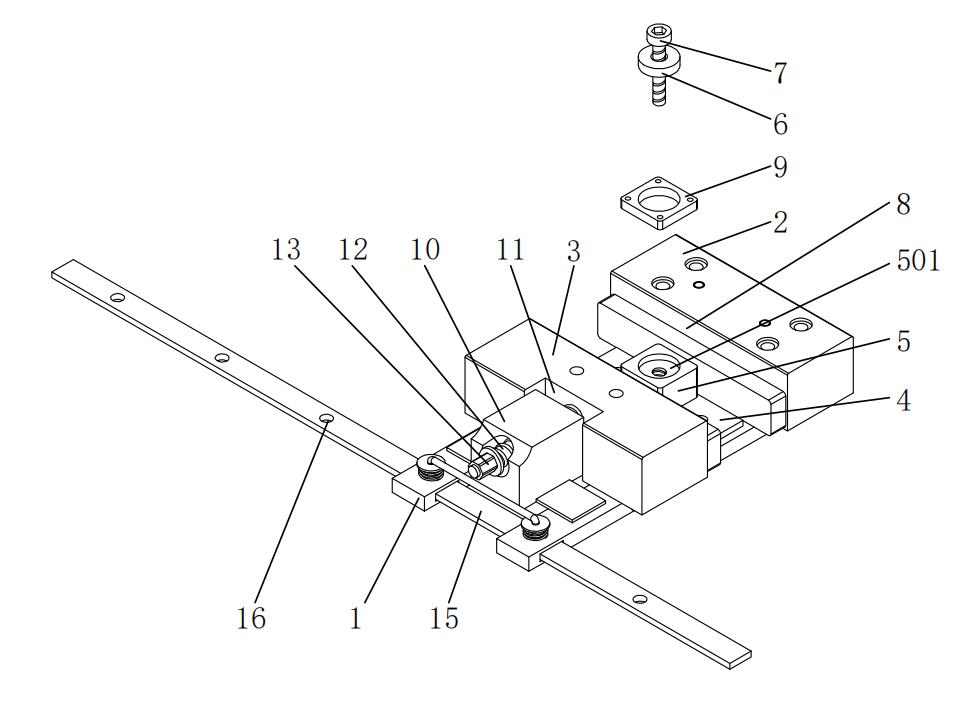

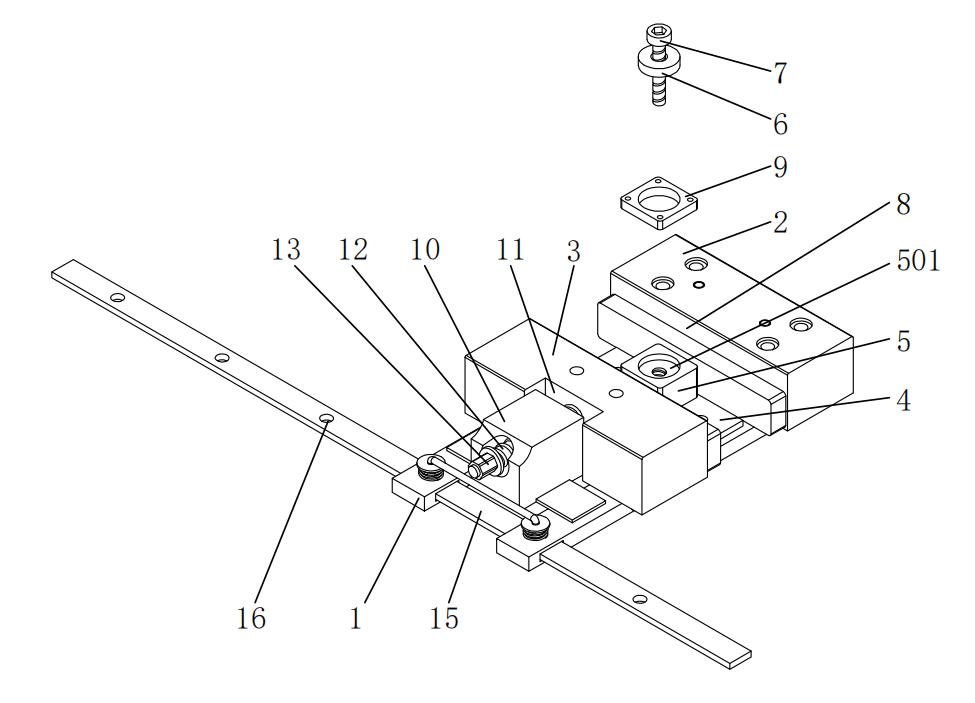

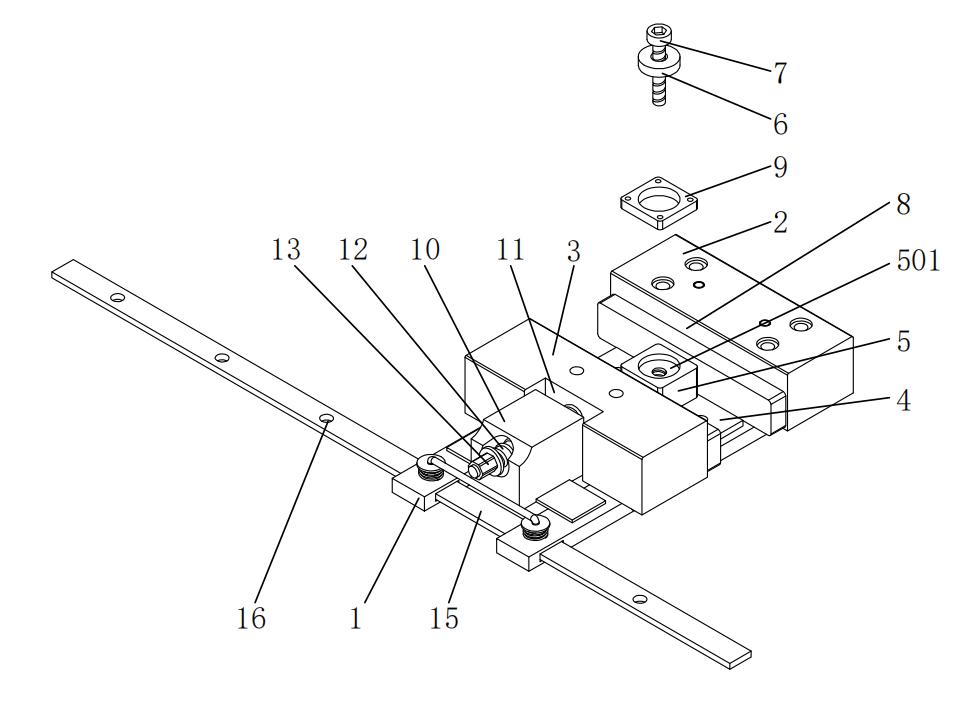

1.1 tres-dimensional clamping Topology

Vertical pressura Imperium:

l Axial vi clausa-loop formatur per compressionem Orbis (VI) et deorsum clamping laminam (IV). Preload vis est pressius imperium ad DCCC ± L n (Din CCLXVII Latin) per densis seras (VII).

l Paribus cum annula sulcus (DI) pro positioning, in finem faciem runout de aeris bushing est ≤ 0.01 mm (ISO MCI).

Lateralis dynamic stabilitatem:

l Fixum / mobilis clamping partes (2/3) capere concavo clamping superficiem (VIII) consilio, augendae in contactu area per XL%. Et uniformitatem lateralibus clamping vis distribution pertingit XCII% (probata cum pressura, sensitive films).

l Integrated adjusting Cochleas (XII) enable micro-feed of ± 0.005 mm, accommodando processus of aeris bushings cum diametris vndique a φ20 ad Φ200 mm.

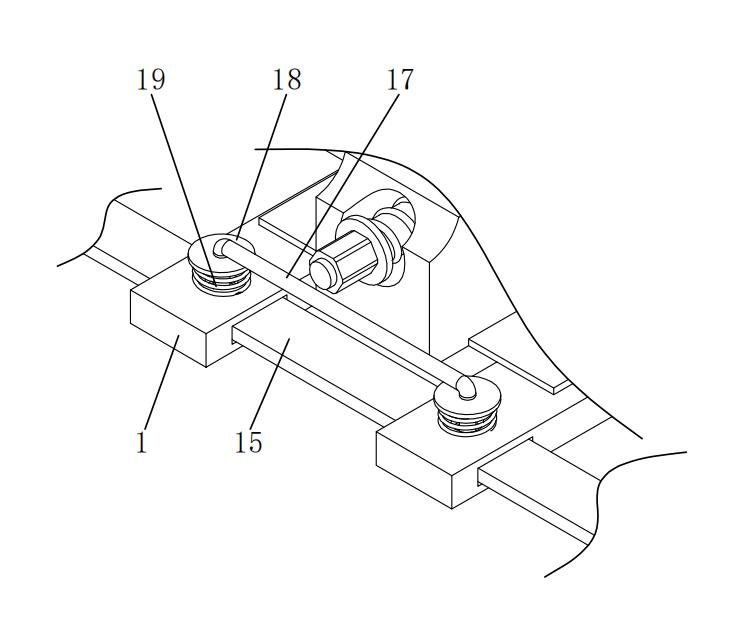

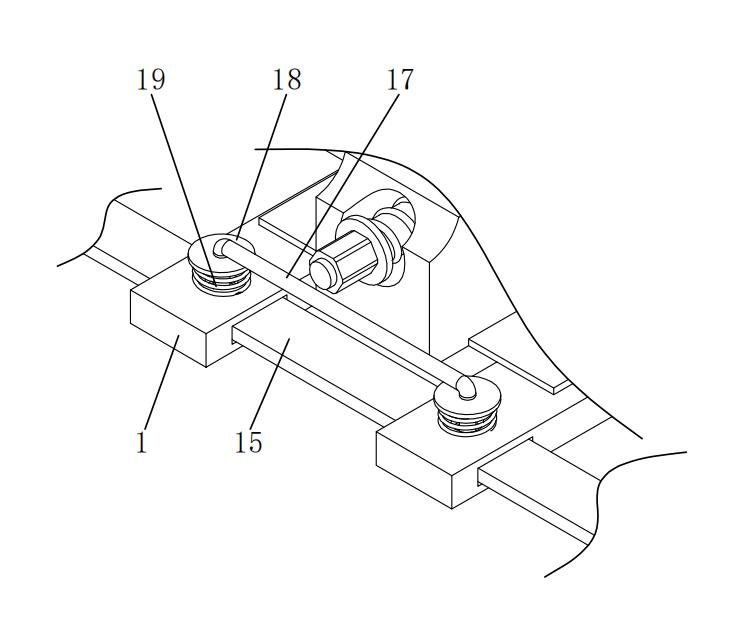

1.2 Vibration Energy dissipatio semita

l A rafaming systematis composito ex fontibus (XIX) et limit annulos (XVIII) Achieves an industria attenuation rate> XVIII DB / S sub HZ 10816-3 Latin).

l Et vibrationis amplitudine per aeris laminam milling regitur XV μm).

II. Graphite Aeris Bushing Processing: Superficiem integritas praesidio technology

2,1 cliping pressura flexibile clamping

Et Flexilis quiddam iacuit technology transfertur aeris bushing fixture:

l Nitrile Flexilis pads (Litus duritia L ± II) sunt in clamping superficiem, reducendo apicem contactu ex XXVIII mpa ad VIII MPA et servatione graphite layer dampnum rate

l Apta ventus Turbine picem afferentem aeris bushings, transiens DNV GL certification et maintaining a friction coefficiens 0.08--.12 ad -30 ° c.

2,2 praecisione positioning multi-foraminis aeris bushings

In coniunctus Positioning est effectum per fila foramina in fundo clamping laminam (IV) et viverra virgis (XVII):

l In loco gradu errorem φ0.5 mm Micro-foramina est ≤ V μm (asme b94.11M).

l Model mutatio tempus reducitur ex XLV minuta ad III minuta, supporting celeri mutandi inter XII foraminis diametrorum.

III. High-praecisione Plate Processing: Anti-deformatio Technology Transfer

3.1 Multi-directional pressura asperitatem consilio

In summitatem clarping laminam (IX) factum est (VI) LXI-T6 Aluminium Alloy, formatam distribui pressura agro in conjunction cum concavo clamping superficiem (VIII)

l Nam 0.5 mm aeris laminis, in planculis est ≤ 0.02 mm / CCC mm (5g basi statione calor calor standard).

l In superficiem asperitas ra valorem est confirmatae ad 0.4 μm, et scelerisque conductivity fluctuation sit

3,2 celeri positus ratio

Modularis consilio de clamping foramina (XVI) et viverra virgis (XVII):

l Sustinet celeri positus de laminam widths ex 300-1200 mm cum repeatability accurate de ± 0.05 mm (VDI MMMCCCXLV).

l Productio efficientiam est auctus per CCC%, et industria consummatio est reducitur per XXV% (ISO (V) I certified data).

III. Key perficientur collatio et ipsa test notitia

| Application sem | Traditional processus | Patented technicae application | Emendationem effectus |

| Graphite layer integritas rate of Graphite aeris bushings | LXXXV% | XCVIII% | XIII% |

| Platformis aeris laminis (0.5 mm) | 0,1 mm / CCC mm | 0.02 mm / CCC mm | LXXX% lenimentus |

| Positioning efficientiam multi-foraminis aeris bushings | XLV minutes / Tempus | III minuta / Tempus | MCD% efficientiam emendationem |

| Machining vibrationis imperium (D HZ) | XV μm | III μm | LXXX% reductionem |

IV. Typical application casibus

4.1 aeris bushings pro novus industria vehiculum motor finis caps

Adoption of multi-directional cohibere magnitudine:

l Et interiore peperit rotunditatis est ≤ 0.005 mm, occurrens in NVH Requirements DCCC V Electric Coegi Systems.

l In Graphite Layer Gerunt rate est <0.1 mg / 10,000 Cycles (Sae J310 test vexillum).

4,2 æstus dissipatio aeris laminas pro semiconductor apparatu

Application of pressura Blancing Technology:

l Et planities est ≤ 0.05 mm / D mm (asme b89.3.4).

l Superficiem asperitas Rs ≤ 0.8 μm, supporting III μm-gradu chip packaging praecisione.

V. Technology extensio et industriae valorem

Cross-productum linea applicationem huius patented technology matrix marcas tres major breakthroughs ad Zhejiang Mingxu:

l Precisione clamping system: inducit in positioning accurate de aere workpieces (± 0.005 mm) in massa productionem aeris-secundum products.

l Superficiem integritas Control, in Graphite Layer / coating praesidio technology reduces ad rate ad sub 0.5%.

l Intencent productio integration: Achieves flexibilia vestibulum per modularem consilio, cum X-complicare incremento in exemplum mutare efficientiam.

Si velis discere magis, placere contactus Miscxu Machinery ad obtinendum completum patent fama: [email protected] .

Nobis loquere