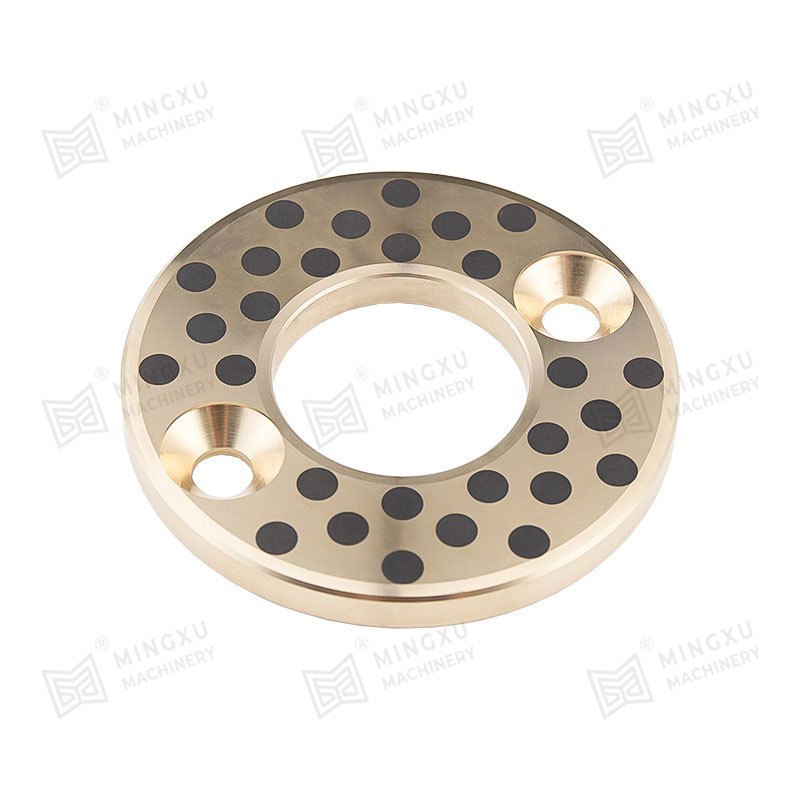

MXB-JTW Metric mitte elementum Vehiculum Transmissionibus

Cat:Sui Lubricating Ferens

MXB-JTW lotores metrici innixi sunt solido robore aerei (ZCuZn25Al6), solido ducatus (graphite vel molybdaeno disulfide) in matrice infixo, ut medi...

Vide Details I. technica background et collaborative innovation valorem

Ut Core elit de auto-lubricating gestus et graphite aeris bushings, Zhejiang Mingxu has extenditur suum patented technology ad aes component processus fixtures ad aeris-fundatur productum lineas, addressing duo major industria points:

l Graphite Aeris Bushing Superficiem Donec: Traditional Clamping modi causa Graphite Layer damnum (damnum rate> XV%), afficiens auto-lubricating perficientur (friction coefficientem fluctuare> XXX%).

l Tenues aeris laminam processui deformationis: aeris laminas cum crassitudine ≤ I mm exhibent a Stamping planities errorem> 0,1 mm (GB / T MCLXXXIV Radiator components.

II. Core Technology Analysis et Collaborative Product Applications

I. Graphite Aeris Bushing Processing: auto-Lubricating Layer Donec Technology

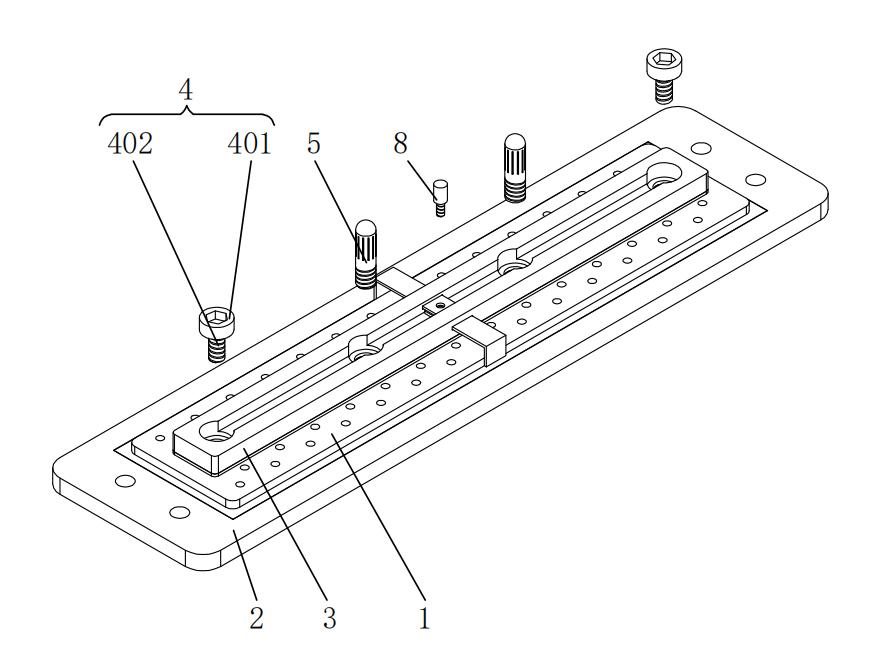

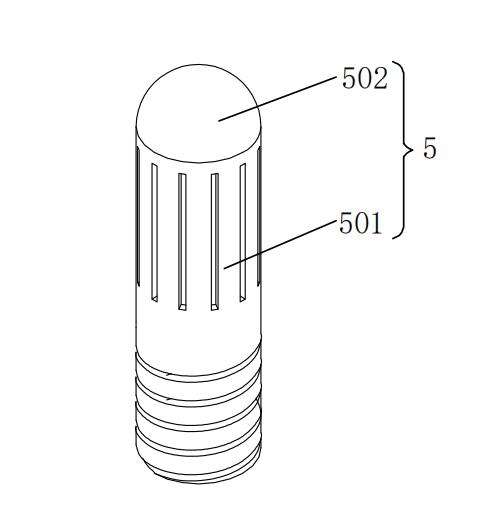

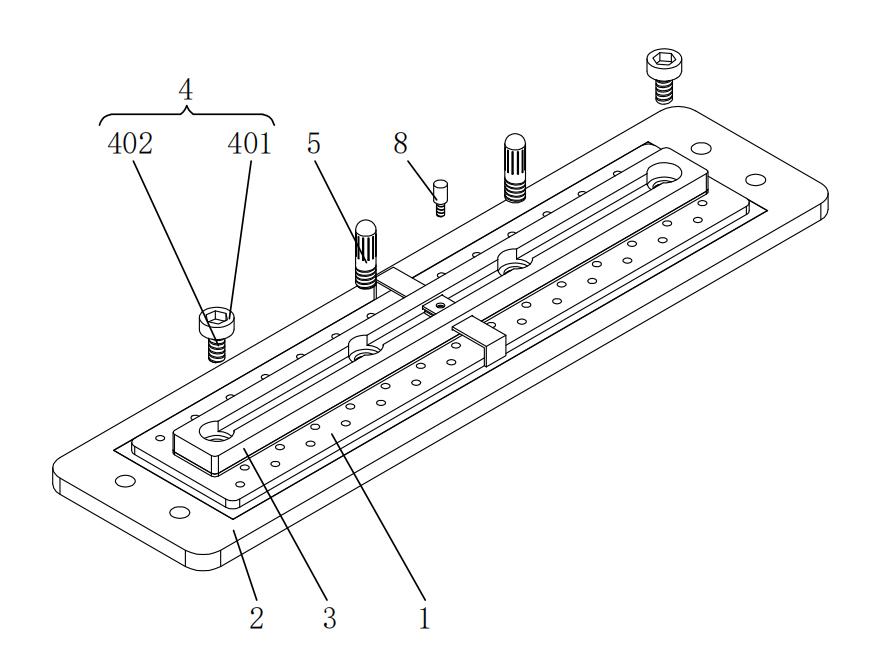

1,1 cliping pressura flexibile clamping

Migration of Composita Flexilis interface technology:

l Patented Flexilis tutela pads (litus duritiem LX ± II) sunt in aeris bushing urgeat formae, reducendo contactu pressura ex XXVIII mpa ad VIII mpa et minimum graphite in damnum ad II% (sem microscopic observatione).

l Pired cum praecisione positioning via duce sagittis (DI), interiore tulit concentus concentus est ad ≤ 0.01 mm (ISO MCI Latin), ensuring uniformis Lubricant distribution.

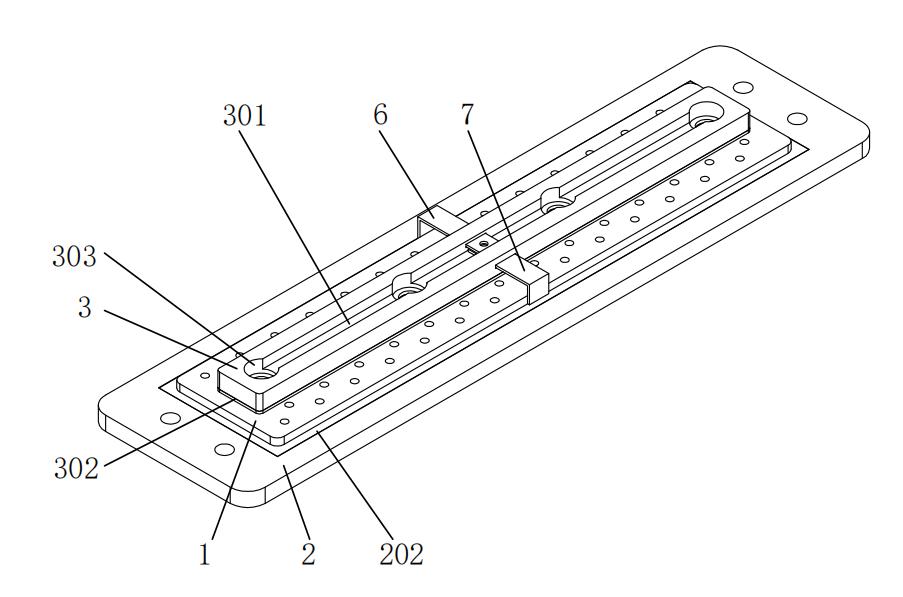

1.2 Vibrationis suppressionem et Micro-damnum imperium

Integration dynamic stabilization technology latus viverra laminas (6/7):

l A lateralis preload vis CC ± X n est applicari per aeris bushing rolling processus, observatio processus vibrationis acceleratio infra 0.5 g (ISO 10816-3).

l Superficies asperitas ra valorem est stabilitur ad 0,4 μm (traditional processus ra = 1.6 μm), extendens in vita ad 8.000 horas (agri-probata in ventum potentia industria).

II. High-praecisione Plate Processing: Anti-deformatio Topology Optimization

2.1 Multi directional flexibile coacte ratio

PRURTIO cum elastica interfaces;

l Et Flexilis tutela pads transferuntur ad aeris laminam Stamping fingit, improving ad uniformitatem contactus pressura a LXXXV% (probata cum pressura-sensitive films).

l Nam 0.5 mm densissima aeris laminis, in planities error est ≤ 0.02 mm / CCC mm, occurrens ad Aau component signa ad 5g basi statione æstus submittit.

2,2 Integration celeri Model Mutare System

Modular Design secundum densis BOLTS (IV):

l Aeris Plate Morte Model Mutare Tempus reducitur ex XLV minuta ad III minuta, accommodando laterem width mutandas inter 300-1200 mm.

l Et positioning accurate est ± 0.05 mm (VDI MMMCCCXLV Latin), et cede rate augetur ad 99,5%.

III. Key perficientur collatio et ipsa test notitia

| Application sem | Traditional processus | Patented technicae application | Emendationem effectus |

| Graphite layer integritas rate of Graphite aeris bushings | LXXXV% | XCVIII% | XIII% |

| Interiorem tulit concentus aeris bushings | 0.03 mm | 0.01 mm | LXVII% praecisione emendationem |

| Platformis aeris laminis (0.5 mm) | 0,1 mm / CCC mm | 0.02 mm / CCC mm | LXXX% lenimentus |

| Aeris laminam Stamping Model Mutare Efficens | XLV minutes / Tempus | III minuta / Tempus | MCD% efficientiam emendationem |

IV. Typical application casibus

4.1 graphite aeris bushings ad ventus Turbine picem gestus

Adoptionem flexibile clamping vibrationis suppressionem solutions:

l Transierunt DNV GL Certification, maintaining a friction coefficiens 0.08-0.12 ad -30 ° C (ASTM D3702).

l Non corrosio post M horas de sal imbre testing (ISO (IX) CCXXVII), et fuit massa-productum pro domesticis V mw offshore ventus turbines.

4.2 altilium calor dissipatio aeris lamines ad novum industria vehicles

Applicationem ex multi-directional pressura buy technology:

l Platness ≤ 0.05 mm / D mm (Catl scriptor Enterprise CTP3.0).

l Thermal conductivity est stabilitur ad CCCLXXXV w / (m K + k) ± III%, supporting ad calorem dissipationem requisita DCCC V summus voltage ieiunium-præcipiens systems.

V. Technology extensio et industriae valorem

Cross-productum linea applicationem huius patented technology matrix marcas tres major breakthroughs ad Zhejiang Mingxu:

l Material interface Engineering: technology technology protegit technology protegit in eget superficies aeris-secundum materiae (Graphite layers / coatings).

l Precisione Vestibulum Ratio: inducit in positioning accurate de aere components (± 0.01 mm) in massa productionem aeris bushings / aeris laminis.

l Viridis productio efficientiam: reducit exemplar mutatio tempus a XCIII% et industria consummatio per XXVIII% (ISO (V) I certified data).

Si velis discere magis, placere contactus Miscxu Machinery ad obtinendum completum patent fama: [email protected] .

MXB-JTW lotores metrici innixi sunt solido robore aerei (ZCuZn25Al6), solido ducatus (graphite vel molybdaeno disulfide) in matrice infixo, ut medi...

Vide Details

MXB-DX ambitus olei liberorum gestuum, aequivalens gestus campestris SF-2 auto-lubricatis vel siccis, quae in lamina ferrea nititur, pulveris sphae...

Vide Details

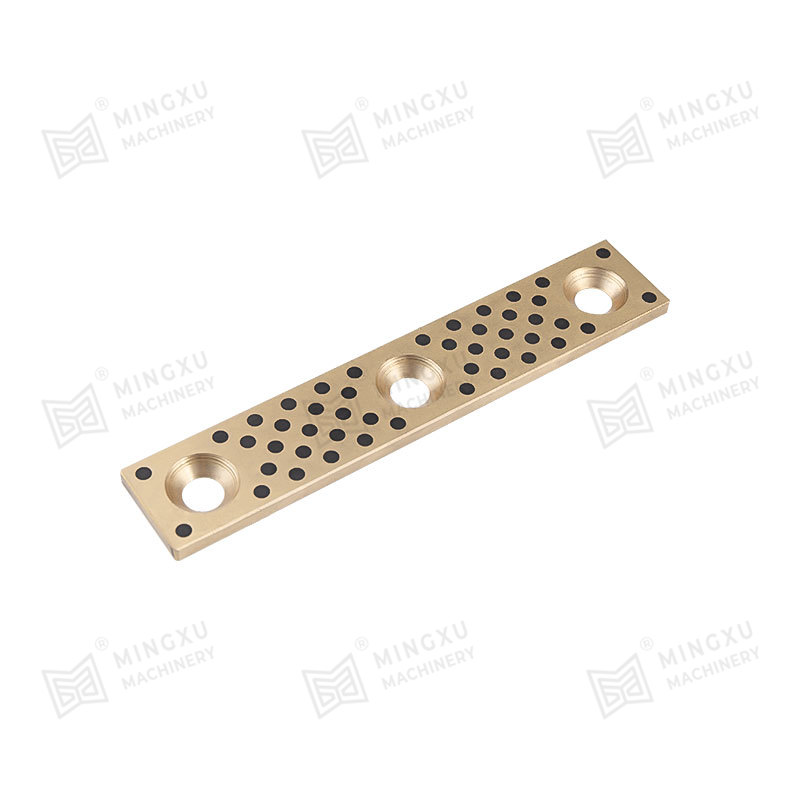

MXB-JESW skate tabulae gravis officiorum skate obsistens est cum 2 foraminibus et 4 foraminibus. Productum normatum est et compatitur notis notis e...

Vide Details

In constructione industriae, MXB-JUWP auto-luctantem bracteae repugnantes maxime adhibentur ad structuras aedificandas tuendas. Per diuturnum tempu...

Vide Details

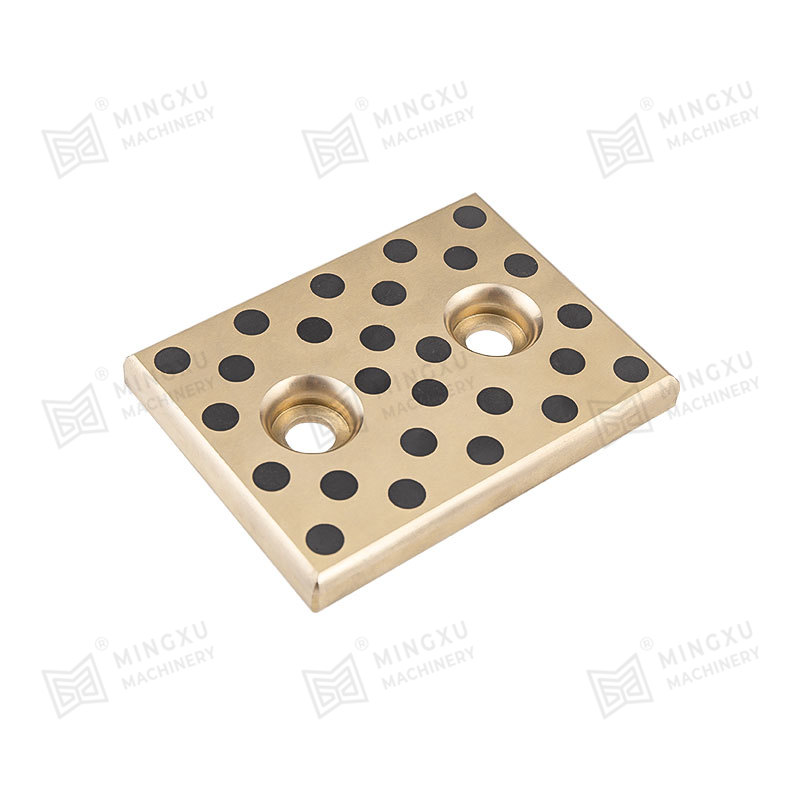

MXB-JOML laminis lapsum auto-lubricantes ordinantur ad frictionem extenuandam et servitium vitae in applicationibus industrialibus extendendis. Pro...

Vide Details

MXB-JSP sui-luctans bracteae obsistentes ad iniectionem machinis fingendis aptae, formae automotivae figurae, machinis tires, machinae officinas (e...

Vide Details

Lamina bimetallica lapsus cum stannum repugnante in tribus lateribus sinteratum est novum genus laminae auto-lubricantis. Comparatio generalis cum ...

Vide Details

SF-1S chalybs immaculata corrosio resistens portatio est valde efficax corrosio-repugnans materia quae formatur volvendo ferro incorrupta ut basis,...

Vide Details

SF-1SS valde corrosio-repugnans et obsistens obsistens gerens e ferro immaculato sicut materia basis et PTFE in superficie spargitur. Haec materia ...

Vide Details

SF-1T formula specialis producti designati ad valorem excelsum PV condiciones operandi oleum calces sentinae. Productum peculiares habet utilitates...

Vide Details

Nobis loquere