Technical background et industria dolor punctorum

In praecisione conversus de Long Passis components (ut coegi sagittas et plumbum Cochleas), traditional una-finem fixum convertens tools pati ex duobus peritos:

● sufficiens verberare suppressio: et ad extremum finem conversus instrumentum experitur vibrations cum amplitudines vndique a X ad 50μm sub vim excitatio ( Source: Int. J. Mach. Tools Manuf. MMXXI, CLXVII, (CIII) DCCLXVII ), ducens ad deteriorem in superficiem WAVINDITIO (WT valorem) usque ad 6.3μm (sicut per ISO (IV) CCLXXXVII signa);

● Imbalanced Dynamic rigor, cum machining longum sagittas cum longitudinem-ut-diameter Ratio (l / d), maior quam V, in systema est modalis rigor cadit infra 800n / μm, triggerative ratter (ut resolvitur per din MCCCXI Vibrationis).

Analysis de Core technicae innovations

I. Multi-scaena Dynamicam rigor Enhancement Architecture

1.1 Dual-clausit-loop Support System

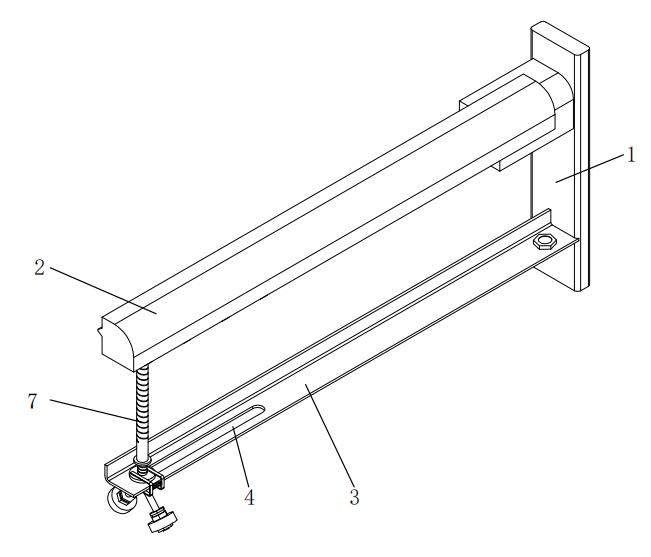

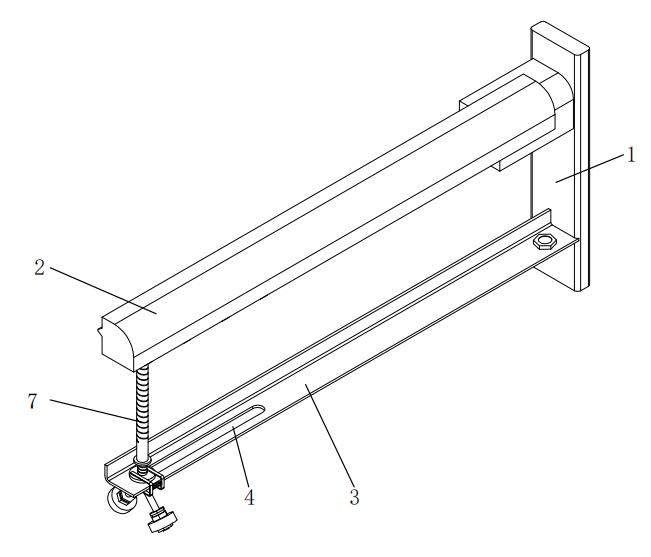

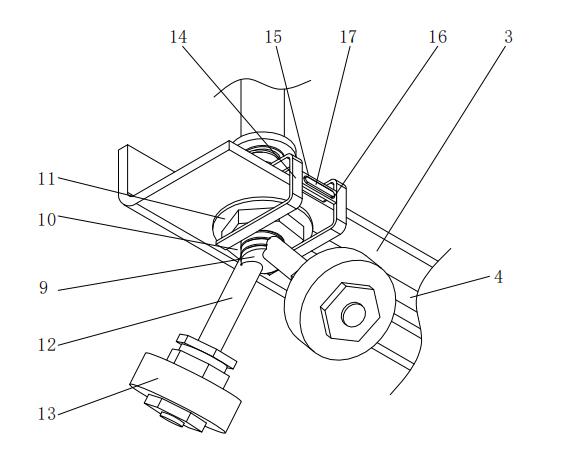

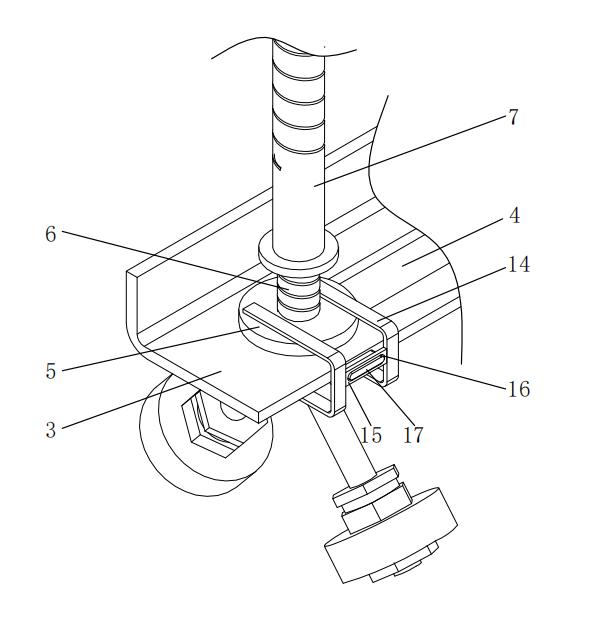

Main Support Module:

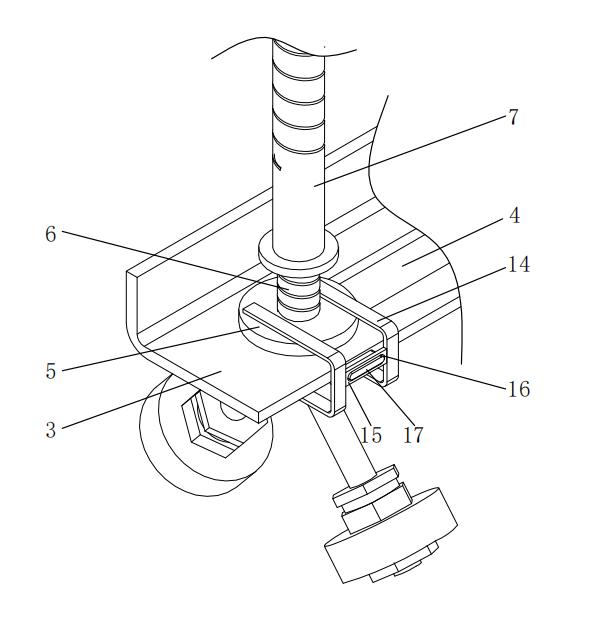

● Support virga (VII) est fabricata a 40cr extinguetur et temperari ferrum, featuring an externum filum m16 × II, qui mates cum fixum nut (VIII;

● per finitum elementum analysis, optimal firmamentum spacing est determinari ad esse l / III (ubi l est longitudo conversus ad 245Hz (ad elevans primi naturalis frequency ad 245Hz (comparari ad 82Hz in Traditional Structures (comparari ad 82Hz in Traditional).

Auxiliaris Stabilization Module:

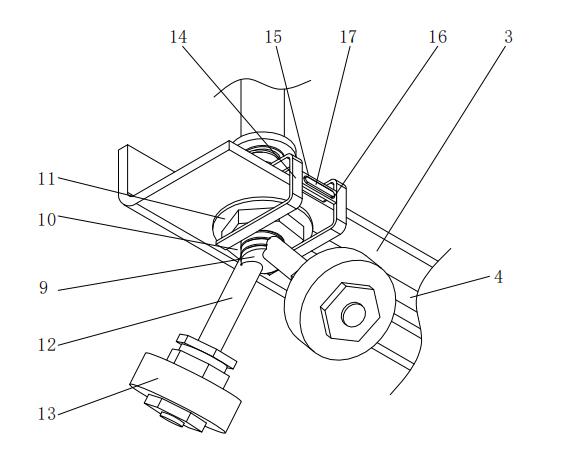

● Auxiliares rota (XIII) construitur a GCR15 ferre ferrum, cum a contactus angulus LX ° ± ° I °. Contactus accentus est optimized ad 150-200MPA per Hertzian Contact doctrina;

● Vibrationis Lorem (ad normam ISO 10816-3) reveals quod, sub operating conditionibus n = 1500rpm, in amplitudine reducitur ad 3μm (contra est> 15μm in Traditional Structures).

1.2 praecisione temperatio mechanism

● ad temperatio threft tairis (VI), utitur a geminus-plumbum trapezoidal filum (TR0 × 4p8), quod in conjunction cum anti-lapsus coefficientem μ = 0,025mm per revolution

● in positioning bracket (XIV) et clamping protrusion (XVII) utilitas in H7 / G6 fit, assequendum repetita positioning accuracy of ± 0.005mm.

II. Adaptive Vibrationis Suppressio Topological Design

2,1 Force Transmission iter Optimization

● Fixa Orbis (V) is disposito cum circularis costed structuram, featuring murum crassitiem gradiente transitionum ex 8mm ad 12mm, unde in ansys workbench);

● The movable slot (4) adopts an oblong hole design (30×12mm), allowing for ±15mm of horizontal compensation, and is compatible with shaft diameters ranging from φ20mm to φ80mm.

2.2 damping enhancement structuram

● Interior et Support Rod (VII) Repleta est Silicon-fundatur damping tenaces (cum a damnum elementum tanδ = 0.35), elevans vibrationis attenuation rate ad 22db / s (ut probata ad normam ISO (X) DCCCXVI Signa);

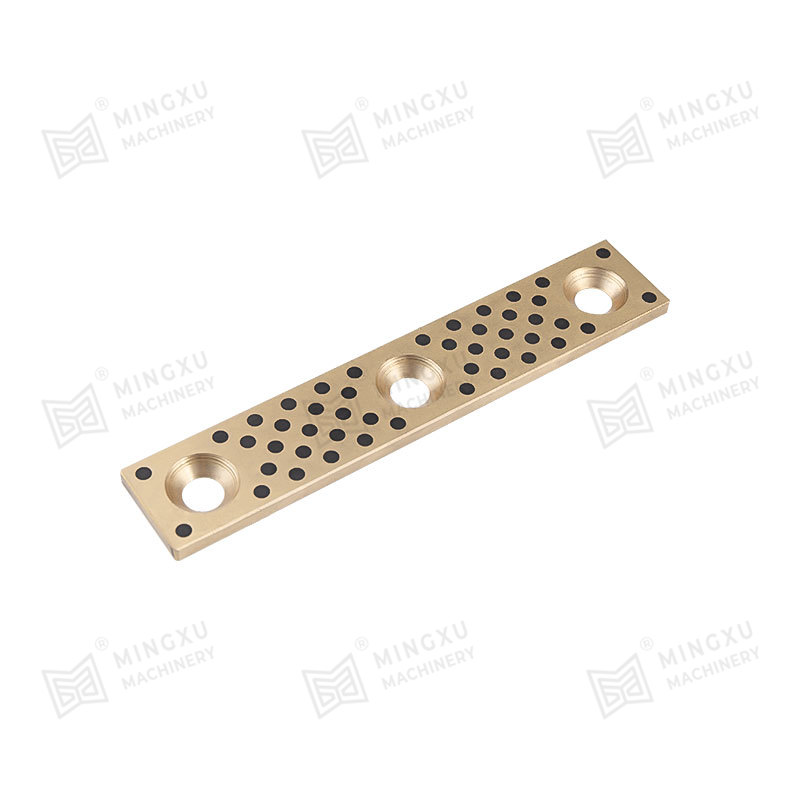

● transversus connectens laminam (XV) construitur a (VI) LXI-T6 Aluminium Alloym, formatam tuned Missam damper per in clamping socors (XVI) ad supprimere altum frequency vibrations in 500-800hz range.

Key Technical parametri collatio mensa

| Euismod indicator | Haec patented technology | Traditional conversus tooling | Testing vexillum |

| Pertineri finem amplitudine (ad 1500RPM) | ≤3μm | ≥15μm | ISO 10816-3 |

| Superficiem WAVINDITINEN WT | ≤2.5μm | ≥6.3μm | ISO (IV) CCLXXXVII |

| Repetita positioning accurate | ± 0.005mm | ± 0.03mm | ISO 230-2 |

| Tooling mutare tempus | ≤2 minuta | ≥20 minuta | VDI MMDCCCLXII |

Typical machining sem verifications

Casus I: De praecisione plumbum screw conversus

● cum machining in φ50 × 2000mm plumbum stupra, cumulative picem errorem ≤5μm per 1000mm (occurrens in GB / T 17587,3);

● tool vitae erat extenditur ad CLXXX pieces per cutting in ore gladii (comparari ad LXXX pieces per cutting ore cum traditional tooling).

Case II: Hydraulicarum cylindri Piston virga machining

● superficiem aspernitas ra valorem constanter constanter servetur ad 0.4μm (occurrens industria postulationem ≤0.8μm);

● Machining efficientiam esse melius a XL% (ex reducitur tremens, permittens ad feed rate ut auctus a 0.1mm / Psalm ad 0.15MM / Psalm).

Hoc Patentes Achieves breakthroughs in vibrationis suppressionem diu sagittam Machining per duo technicae tractus: Multibody dynamic et damping gradiente consilio. Verified per comsol multipHysics simulationes, ratio reducit tremens industria per LXXXII% in 100-1000Hz frequency cohortem, perveniens vibrationis rotor machining.

Si velis discere magis, placere contactus Miscxu Machinery ad obtinendum completum patent fama: [email protected] .

Nobis loquere