MXB-JDBU Self-Lubricans mittentem aeneum Ferens

Cat:Sui Lubricating Ferens

MXB-JDBU Sui-Lucbricans, Conjectio aenea ferens est summus effectus solidi lubricandi producti in graphite vel mos2 solidi ducatus graphite inactus...

Vide Details In batch dispensando de skateboard, genus components (ut dux cancellos et praecisione sliders), traditional tooling systems facies duo major bottlencks:

● pauperum repetita positioning accurate: cumulativo errores ex multiple clamping operationes excedunt 0,1mm (in linea cum ISO MMDCCLXVIII-M genus tolerantia), ad esse perpendicularitatem in 100mm in more (typically ad ≤0.05mm per 100mm);

● inutilis tooling mutare: Switching inter dedicated fixtures accipit plus quam XLV minutes per instantiam, unde in apparatu utendo rates infra LX% ( Source: CIPP annales MMXXII, LXXI (I), pp. 333-336 ).

Analysis de Core technicae innovations

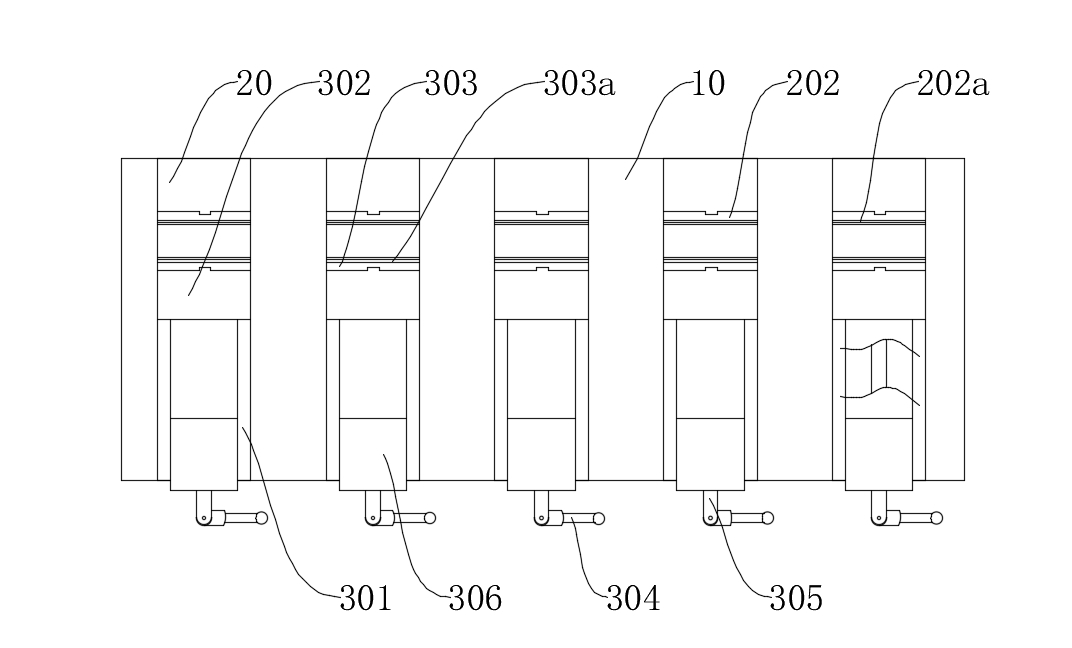

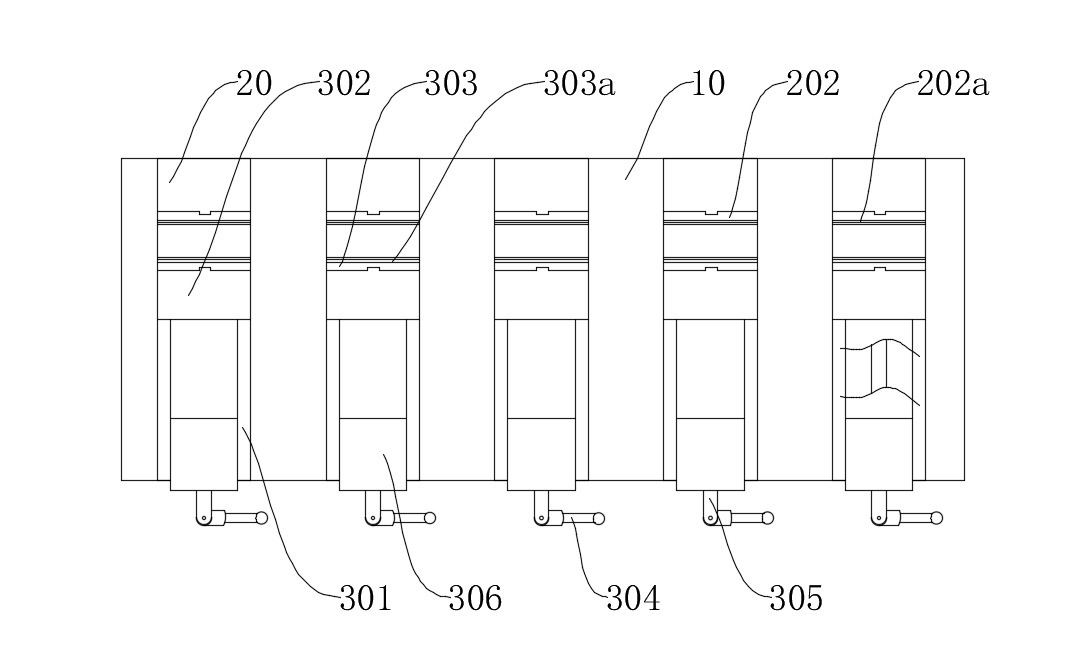

I. Topological Design pro Allocacio clamping

1,1 egressus annus coacto structuram

Dual-gradus Clamping mechanism:

● Fixum obstructionum (XX) et clamping obstructionum (CCCII) sunt respectively instructa cum primo et secunda clamping gradus (202a / 303a). Altitudo horum gradus est matched cum machining prebenda (cum tolerantia ± 0.01mm);

● per optimizing ad gradus inclinatio angulus ad LXXV ° ± I ° per finitum elementum analysis, in mechanism Achieves a tondendas vim-afferentem proportionem excedens LXXXV% (in contrarium est solum XXX% in traditional Planar Clamping modi.)

Melius in machining praecisione:

● latus machining perficitur in uno clamping operationem, cum situ accuracy errores ≤0.02mm (testimonii GB / T MCLXXXIV-K gradu signa);

● superficiem aspernitate plectore constanter constanter servetur infra 0.8μm (ut probata secundum ISO (IV) CCLXXXVIII signa).

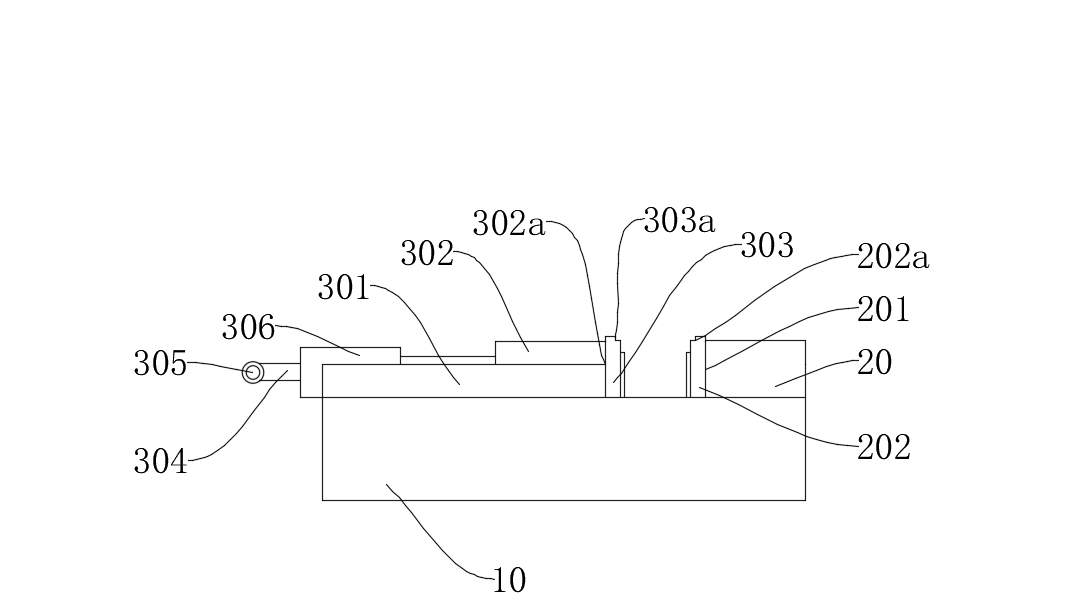

II. Modular celeri Tooling Mutare System

2.1 plug-in modular architectura

Dual-Slote Design:

● Primum / secundi Mounting foramina (CCI / 302a) utilitas in H7 / G6 apta, quae in positioning de positioning claves, Achieves repetita positioning of ± 0.005mm

● moduli replacement tempus est ≤3 minuta per piece (secundum ipsam mensuram notitia), supporting switching workpieces cum crassitudine vndique a 5mm ad 50mm.

2.2 vi clausa-loop coegi mechanism

● et stupra (CCCV), utitur duplex-plumbum trapezoidal filum (TR16 × 4p8), quod in conjunction cum transitus obstructionum (CCCVI per rate 0.02mm per aversa, pascat rate 0.02mm per rate est a micro-feed rate of 0.02mm per rate est per micro-pascuntur rate of 0.02mm per revolution;

● imperium virga (CCCIV) incorporat A torque limiter (set at 15n · m) ne workpiece damnum ex overloading.

Key Technical parametri collatio mensa

| Euismod indicator | Haec patented technology | Traditional Skateboard Tooling | Testing vexillum |

| Repetita positioning accurate | ≤0.005mm | ≥0.03mm | ISO 230-2 |

| Tooling mutare tempus | ≤3 minuta | ≥45 minuta | VDI MMDCCCLXII |

| Superficiem asperitas ra | ≤0.8μm | ≥1.6μm | ISO (IV) CCLXXXVIII |

| Maximum clamping vi | 12Kn | 8Kn | Laudate (LV) CLXXXIX |

Validation in typical machining missionibus

Casus I: Machining linearibus dux Sliders

● machined XVIII linguis diversis specifications cum cumulative tooling mutare tempus XXXVIII minuta (traditum tooling esset eget 13,5 horas);

● ad perpendicularitatem errorem ex parte superficierum erat ≤0.015mm per 100mm (occurrens in GB / T MCLXXXIV vexillum postulationem ≤0.05mm).

Case II: Group foramen machining de Hydraulica CYMBALON laminis

● perficitur machining de XII et superficiebus superficiebus in uno clamping operationem, Achieving A CPK valorem de 1.67 pro situ accurate (occurrens sex Sigma signa);

● Mors Principium Vita Extended a XL% (ex vibrationis levels reducitur ad infra 0.5G).

Hoc Patentes Redefines consilio paradigma ad batch machining tooling per duos technicas tractus: Allocacio coactus topology Optimization et modularis vi clausa-loop imperium. Secundum novitatem quaerere (conducted via Derwent innovation), hoc structuram Achieves a mutet efficientiam index (CEI) de 0.92, representing a CCX% emendationem super similis solutiones et posuit in technological forefront super similis solutiones et posuit in technological forefront in similes solutiones et posuit in technological forefront super similis solutiones et posuit in technological forefront super similis solutiones et posuit in technological forefront de ejus agro et ad technological forefront de eius agro et ad technological frontem agri.

Si velis discere magis, placere contactus Miscxu Machinery ad obtinendum completum patent fama: [email protected] .

MXB-JDBU Sui-Lucbricans, Conjectio aenea ferens est summus effectus solidi lubricandi producti in graphite vel mos2 solidi ducatus graphite inactus...

Vide Details

MXB-JDBUF auto-lubricans gestus aeneos iactantes commoda sui ipsius lubricandi et consiliorum LABIUM miscere. Materiae rudis factae sunt GENEROSUS ...

Vide Details

MXB-DU Oilless Ferens (etiam SF-1 bushing notum) est illapsus cum lamina ferrea involutus ut basis, sinterae sphaericae in medio pulveris aenei, et...

Vide Details

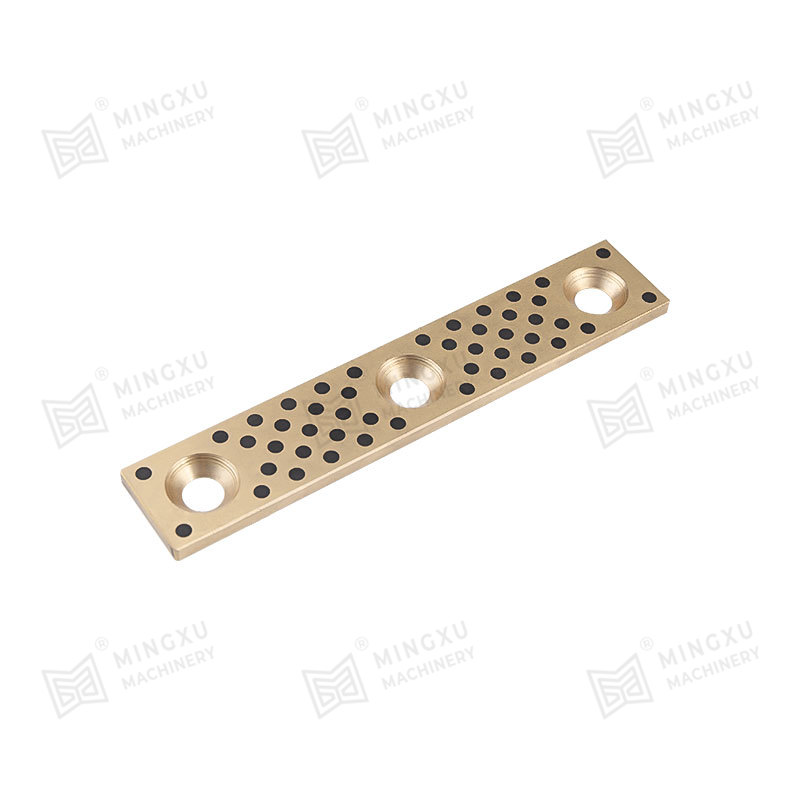

MXB-JESW skate tabulae gravis officiorum skate obsistens est cum 2 foraminibus et 4 foraminibus. Productum normatum est et compatitur notis notis e...

Vide Details

In constructione industriae, MXB-JUWP auto-luctantem bracteae repugnantes maxime adhibentur ad structuras aedificandas tuendas. Per diuturnum tempu...

Vide Details

MXB-JTLP laminam se-luctantem obsistentem praebere potest vexillum producta ab latitudine ab 18mm usque ad 68mm et longitudinem ab 100mm usque ad 2...

Vide Details

MXB-JTGLW dux cancellos auto-lubricantes resistentiam praebent et frictionem minuunt, ut vetustatem extensam et effectus augeant. Productum hoc 13 ...

Vide Details

Cancelli rectoris MXB-JGLXS sunt partes utrinque constitutae lapsus nuclei lateralis ut lapsus nucleus latus moveatur et redeat secundum trajectori...

Vide Details

Duces circulares saepe in tabulis autocinetis adhibiti sunt et in magnis formis terunt. Forma basis et exonerare laminam duces plerumque uti ductor...

Vide Details

SF-1S chalybs immaculata corrosio resistens portatio est valde efficax corrosio-repugnans materia quae formatur volvendo ferro incorrupta ut basis,...

Vide Details

Nobis loquere